Is precise welding and painting necessary for the quality of your complex CNC machined parts? P4Swiss/Lindel excels at manufacturing highly qualified CNC machined parts while, also, efficiently providing Advanced Project Management! High-Quality CNC Machining for Driverless Semi Trucks Because of our highly advanced milling abilities and lathes, we are able to manufacture precise complex parts. Our quality team efficiently manufactured three separate milled and lathe turned parts. As a result, providing high-quality and precise parts for driverless semi trucks. We have two certified welders who assembled these parts, efficiently welding the aluminum parts together. Afterwards, it was necessary to blend

Read more about CNC machining in Tucson →CNC Mill Machines allow us to efficiently manufacture small, complex and precise CNC machined parts. What We Excel At At P4Swiss/Lindel, our quality team excels at small complex short run production. We not only have 3-axis and 4-axis machining, but 5-axis CNC mill machines, as well. There are some CNC machine shops that will only manufacture with 3-axis or 4-axis CNC machining. Here at P4Swiss/Lindel, we efficiently utilize the advanced 5-axis CNC milling machines. As a result, we can provide our customers a shorter turn time experience. We are, also, able to offer completed mill runs from 25 to

Read more about CNC machining in Tucson →There’s a lot to be said for lean processes and building efficiencies in a production environment. But when it comes to support after the sale, cutting corners is a risk the team at P4Swiss / Lindel refuses to take.

Read more about CNC machining in Tucson →For more than three decades, the team at P4Swiss / Lindel have been helping manufacturers throughout the United States produce state-of-the-art machined parts for some of the most advanced machinery on the planet (and beyond). Success stories like these, though, often start with humble origins. Each precision part, whether machined for medical or optical manufacturing, military / defense contractors, or aerospace engineers, starts with a custom prototype. No matter if it’s as a new component within a precision manufacturing workflow or to innovate a current complex part through testing materials or alternate CNC machining techniques, the prototyping stage is often

Read more about CNC machining in Tucson →CNC machining, for decades, has been the manufacturers’ choice for precision manufactured parts. From the medical industry to defense contractors, agricultural manufacturers, and more, the demand for ever more precision, speed and complexity on smaller parts has been on the rise. With P4Swiss / Lindel Precision CNC Machining’s 5-Axis CNC capabilities, customers not only take advantage of the precision of computer numerical controlled (CNC) production, but also the accuracy and efficiency of this multi-axis set up. Check out the latest 5-Axis CNC machined parts from P4Swiss / Lindel in our production gallery (click here). While many CNC machines work on

Read more about CNC machining in Tucson →When the medical industry or defense contractors need reliable precision machined components, they turn to the Swiss CNC machining expertise of P4Swiss / Lindel. Their ability to consistently manufacture quality, complicated machined parts supports a variety of essential industries we rely on every day. A recent custom order posed a unique challenge for the CNC Swiss machining team. Specifications for the component to be used in a defense manufacturing operation were small and complex, with a length of only two inches, a narrow, tapered tip, and a threaded collar. It was necessary to get inside the collar without damaging the

Read more about CNC machining in Tucson →When 2020 opened, the team at P4Swiss / Lindel CNC Manufacturing were riding high on their recent merger and the anticipation of growing the CNC Mill/Lathe and Swiss CNC manufacturing market. With news of custom CNC parts produced by the P4Swiss / Lindel heading into space and increasing capabilities across the operation, the news of potential industry downturn and international pandemic meant pivoting on plans and making adjustments to meet demand in a slightly different market landscape. After assessing the initial impact of COVID-19, keeping the P4Swiss / Lindel team and their clients safe was at the top priority,

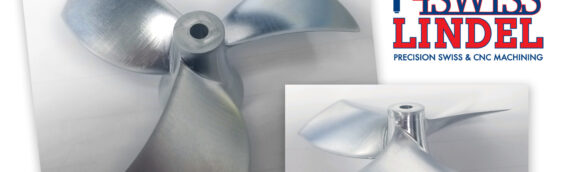

Read more about CNC machining in Tucson →The manufacturing sector has seen a steady increase in demand for small complex parts and P4Swiss / Lindel has met and exceeded the call. Excelling in complex precision machined parts, P4Swiss / Lindel Precision CNC has the team and the tools to fill your custom order. Recently, P4Swiss / Lindel was called upon to manufacture an underwater propeller to meet very precise specifications for use on small unmanned water craft. With the specifications of the part needed, the P4Swiss / Lindel team got to work on machining the small complex part to precisely match the Solid Model File (similar to

Read more about CNC machining in Tucson →Keeping up with growth in the manufacturing sector, P4Swiss / Lindel CNC Machining recently grew their stable of tools. A Doosan Puma 2100SY lathe was recently purchased to help keep up with demand. Doosan’s Puma 2100SY is a high performance lathe, designed for precision CNC production and premium surface finishes. With a max turning length of 20”, max turning diameter of 16″, and a chuck size of 8”, this machine can get the work done on some of the toughest materials ranging from steel and aluminum to titanium alloys and more. Click on the images below to see a gallery

Read more about CNC machining in Tucson →Precision CNC machining and Swiss CNC machining require the ability to produce custom machined parts quickly, efficiently and at a cost competitive within a very full market. Demanding industries like military and defense manufacturers and medical manufacturers need to know they have a CNC machining partner that can provide precision at every level and for orders of any size. At P4Swiss / Lindel CNC Machining, our team runs three 5-axis CNC machines with work envelopes ranging up to 12”. Each piece engineered for these machines can be produced faster and more accurate than competing CNC machines due to its ability

Read more about CNC machining in Tucson →