Complex Parts Are No Problem For Lindel

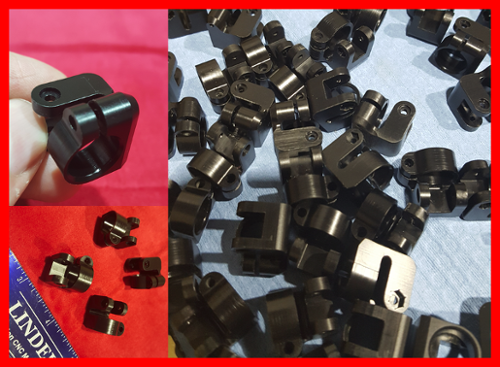

Just the other day a customer came to us and asked if we had the capability to machine one of their more complex parts they had designed. They were in need of some parts in 2-3 weeks with several more every week after that for the next 4 weeks. Our team reviewed the project and accepted the challenge. You can see the result of our efforts below. Our 5-Axis machine completed a majority of the features and one of our 3-Axis machines finished the base of the part to make the part complete in two operations. This is another example

“Is your business seasonal”?

I often have people ask me “Is your business seasonal”? Sometimes before I get a chance to answer they have their next question ready, “When are your busy or slow times”? With almost 20 years of contract manufacturing experience I have personally found that we are “cyclical rather than seasonal”. We have busy and slow times but I have found it near impossible to predict when they will be. Some of you may be familiar with the expression “Feast or Famine” At times it seems like this to us depending on our current workload. We just are coming out of a period of having a little

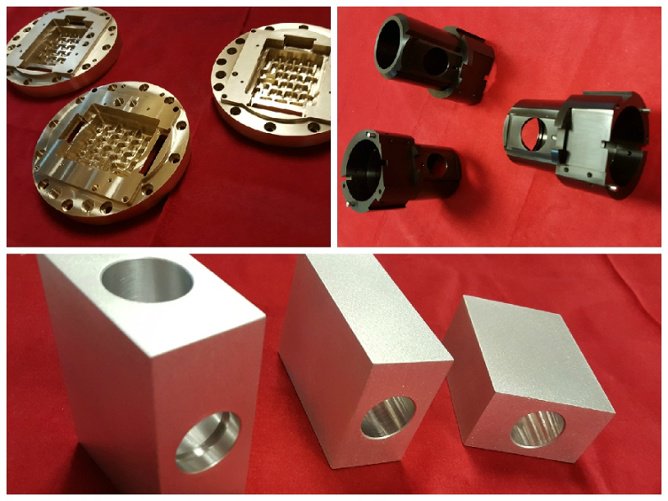

8 separate operations reduced to 2

Before we invested in a 5 Axis CNC Mill we had been making these parts on 3 Axix CNC Mills. The 3 Axix Mills required 8 separate operations. Each requiring a separate set up and first article. This proess took about 2-3 weeks to complete. When we proammed this for the 5 Axis CNC Mill we were able to reduce the operation from 8 down to two. Once this was completed our production time was reduced from 2-3 weeks down to 2-3 days. A significant savings in production time and lead time. We now have three 5 Axis CNC mills.

Precision CNC Machining from raw material

Hello and welcome to my precision cnc machining blog. Precision cnc machining is the cornerstone of building and creating dreams. Starting from raw material and ending with a precision engineered, multi featured workpiece that functions as it was designed. By utilizing a variety of equipment including lathes, mills, Gibbs programming software and superior inspection equipment we are able to deliver products that stand above the competition. We specialize in Medical Device Manufacturing, Aerospace, Defense and Optical parts. With more than 30 years in the machining business, we understand the importance of quality, communication and delivering as promised. Do you have

Increasing Precision CNC Machining business

In my last 2 blogs I’ve talked about the process of a machined part from start to finish. I will be continuing that series next month but today I’d like to side step a bit and talk about something very exciting that will impact your next project-Lindel Precision CNC Machining is very proud to introduced 2 new machines into our shop. Last week our new Aberlink CMM inspection machine was delivered. The addition of our new Aberlink CMM machine will help eliminate inspection bottlenecks. Measures approximately 20% quicker than standard variant making it ideal for high volume measuring. The Axiom

A Machined Part from Start to Finish-Milling and Axis

In this blog I’m going to talk a little about the different milling machines and the axis that are commonly used in a machine shop, but first let’s define a Mill and an Axis. A mill is a machine tool for rotating a cutter (milling cutter) to produce or formed surfaces on a workpiece, usually by moving the work past the cutter. An Axis is a fixed reference line for the measurement of coordinates, an imaginary line about which a body rotates (Source:Dictionary.com). Now that we know what each of these are defined as let’s talk about the different axis

A Machined Part From Start To Finish

The complexity of a part depends on several factors. The beginning of a machined part is the foundation of a successful product. It all starts with an idea, of course, but that idea needs to be translated properly and accurately in order for the part to have the desired outcome. The universal communication tool that is used is the Partprint and solid model. The prints and model will have everything a machine shop needs to know to understand what the engineer is trying to accomplish, what the final part will look like including any special features that should be added

Project Management, Making the Change

Project management means a lot of different things to a lot of different people, right? To most it means doing what you say and delivering on time or at least communicating with the client during the stages of production but how many times have you heard, once you submit an RFQ with your requested lead time, that your supplier can meet your delivery request only to have the infamous “crickets chirping” when asked WHERE IS MY ORDER! I would have to guess that 90% of the time reps are just saying what they ‘think’ you want to hear in order

OSIRIS-Rex Our Contribution To Science

Our Contribution to science: In 2013 Lindel Engineering received a request from the University of Arizona regarding a project that they were working on. U of A was in the development of a camera housing unit that would consequently be launched into space. This camera housing and satellite that it would be traveling in, developed in partnership with NASA, University of Arizona and many others including Lindel Engineering would find itself being launched into space on Sept 8th, 2016. As we approach the one year anniversary of its launch Lindel Engineering would like to share with you a little story

- « Previous

- 1

- …

- 4

- 5

- 6