Custom CNC Machining vs. Mass Production: Which One Is Right for Your Project?

In today’s competitive manufacturing landscape, choosing the right production method can significantly impact the success, cost and efficiency of your project. While large-scale production runs offer high output at a lower cost per unit, custom CNC machining provides the flexibility, precision and quality that many specialized applications require. This guide explores the key differences between custom CNC machining and mass production. Whether you’re developing a prototype, planning a limited run or scaling for the long term, understanding these two approaches will help you make an informed decision that aligns with your product goals, tolerances and budget. What Is Custom CNC

How to Select the Right CNC Machining Material for Your Application

Choosing the right CNC machining material is one of the most critical decisions in manufacturing. The material you select will determine your part’s durability and functionality. At P4Swiss | Lindel CNC Machining, we specialize in manufacturing a wide range of non-ferrous and exotic materials. Our expertise ensures that we can help you choose the best CNC machining material to meet your project’s specific needs. Understanding the Importance of CNC Machining Material Selection Selecting the right CNC machining material is essential for achieving optimal performance in your final product. The material will impact factors such as strength, weight and corrosion resistance.

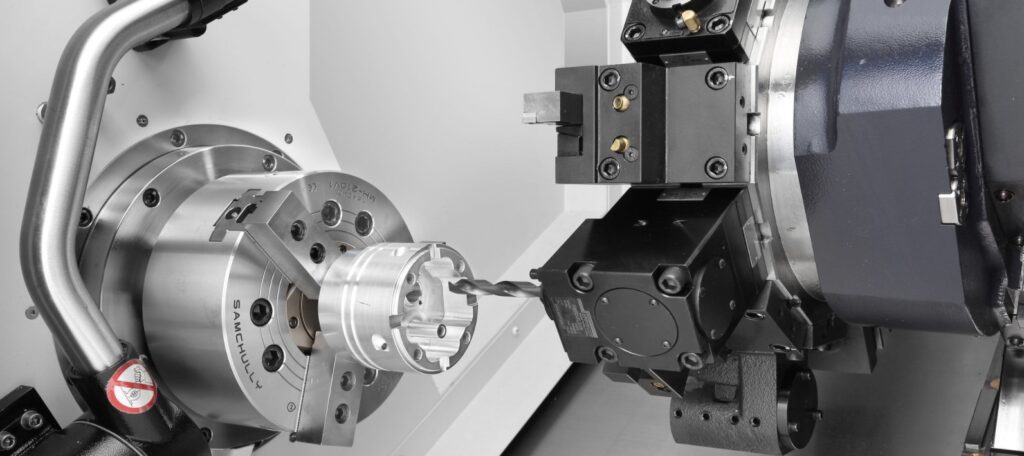

What Is the Difference Between CNC Machining and Swiss Machining?

For businesses seeking high-precision machined components, finding a manufacturing solution that balances precision and efficiency can be a challenge. In sectors like aerospace, medical, optical and defense, companies rely on intricate, reliable parts that meet strict tolerances. However, not every machining process delivers the level of accuracy or scalability required for these demanding applications. Two methods – CNC machining and Swiss machining – are known for producing high-quality parts. Each machining process has unique advantages, limitations and ideal use cases. But what’s the difference between them, and which one is better suited for specific applications? This blog will delve into

A Case Study on CNC Machining Tungsten Material

In the realm of CNC Machining, not all materials are created equal. Some materials – like aluminum and steel – present routine challenges that most machine shops are equipped to handle. However, other materials – like tungsten – raise the bar. As a matter of fact, Machining Tungsten can overwhelm even the most experienced machinists with its complexity. This blog post delves into a fascinating case study in which our team at P4Swiss/Lindel CNC Machining rose to the challenge. Essentially, we engineered a successful strategy to manufacture a particularly demanding tungsten part that many other machine shops refused to even

How To Choose The Right CNC Shop

Choosing the right CNC Shop is crucial for any project that involves CNC manufacturing. Whether you’re in the aerospace, medical, optical or defense industry, the quality of CNC machining can significantly influence the final product. Here are some key factors to consider when selecting the right CNC machine shop to ensure your projects are successful and your parts are manufactured to the highest standards. 1. Experience and Expertise When you’re delving into the realm of CNC machining for your projects, understanding the experience and expertise of a CNC shop is crucial. Here’s a detailed look at why experience and expertise

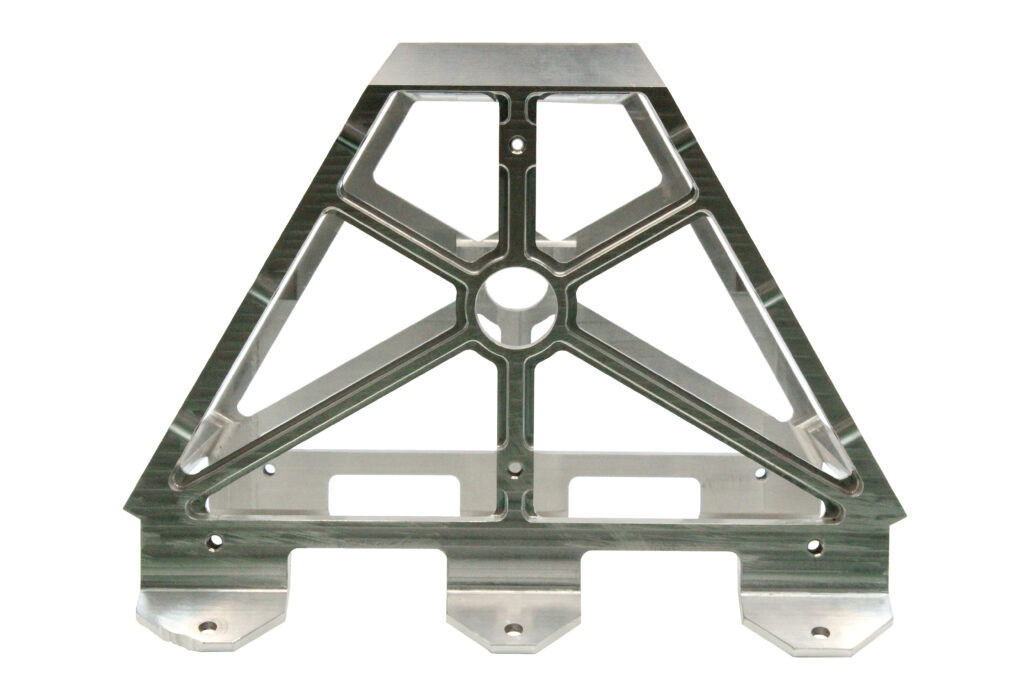

Custom CNC Machining: Telescope Parts

In the world of precision CNC manufacturing, every project brings its unique set of challenges and rewards. But sometimes, a project comes along that tests our capabilities. Such was the case with our recent collaboration with the Giant Magellan Telescope Organization (GMTO). Our journey with GMTO began when they approached us with a Custom CNC Machining project that was compelling and exciting. The task? To manufacture a series of intricate CNC milled parts that would contribute to the construction of a telescope. Unlike most projects that involve producing single item part numbers in various quantities, this endeavor required us to

Expanding Our Operations In CNC Machining

In the dynamic landscape of precision manufacturing, the recent acquisition of Western Automatic Machining, Inc. by our company P4Swiss/Lindel CNC Machining marks a significant milestone. As a leader in CNC manufacturing services, our company’s expansion in Tucson, Arizona is not just about growing our footprint – it’s about merging expertise, technology and capability to deliver unparalleled precision and quality in machining services. A Strategic Move For Enhanced Capabilities In November 2023, P4Swiss/Lindel CNC Machining acquired a company that’s renowned for its precision machining services – Western Automatic Machining, Inc. “I have chosen to sell Western to P4Swiss/Lindel because I believe

CNC Machining For The Defense Industry

Why should you, as a manufacturer, commit to the CNC Machining process for your complex and intricately designed defense components? The defense industry needs access to high quality machined components that can guarantee proper placement in defense equipment. Not only that, but a defense part should have the ability to withstand maximum use in extreme environments without malfunctioning or breaking down. For that reason, attention to detail cannot be spared, especially when it comes to defense CNC machining. A 5-axis CNC machine can manufacture the complex geometries and tight tolerances that are critical for the successful operation of your defense

Please Welcome Bill Thomasson: Our New General Manager

The manufacturing sector is constantly changing, advancing and growing. In recent years, there has been a significant growth in fabricators who need precision machined parts for production operations. Complex geometries and demanding tolerances are frequently being sought after. With that being said, Precision Machining has become critically important for a vast majority of industries. Precision Machining has the ability to produce the precise, complicated and intricately designed parts without any errors. Part of our strategy, here at P4Swiss | Lindel CNC Machining, is properly maintaining the increase in demand for precision machined parts. To help us do that, we have

The CNC Machining Process For Aerospace Components

An error on an aerospace component will, ultimately, result in an immense safety hazard. For that reason, it is essential that human errors are prevented during the machining process, which will, in turn, reduce the risk of a faulty part being produced. The CNC Machining Process is capable of fabricating the complex aerospace components that have intricate geometries. Multiple manufacturing procedures can be performed on a part simultaneously with a CNC machine. Because of this, the machinery has the ability to manufacture specific specifications and significantly tight tolerances. In the realm of aerospace, this is immensely important, as aircrafts and