Utilize Our New CNC Machinists & Increased Production Capacity

P4Swiss / Lindel CNC Machining has been taking the recent challenges with the manufacturing industry and turning them into a value-added opportunity for our customers…

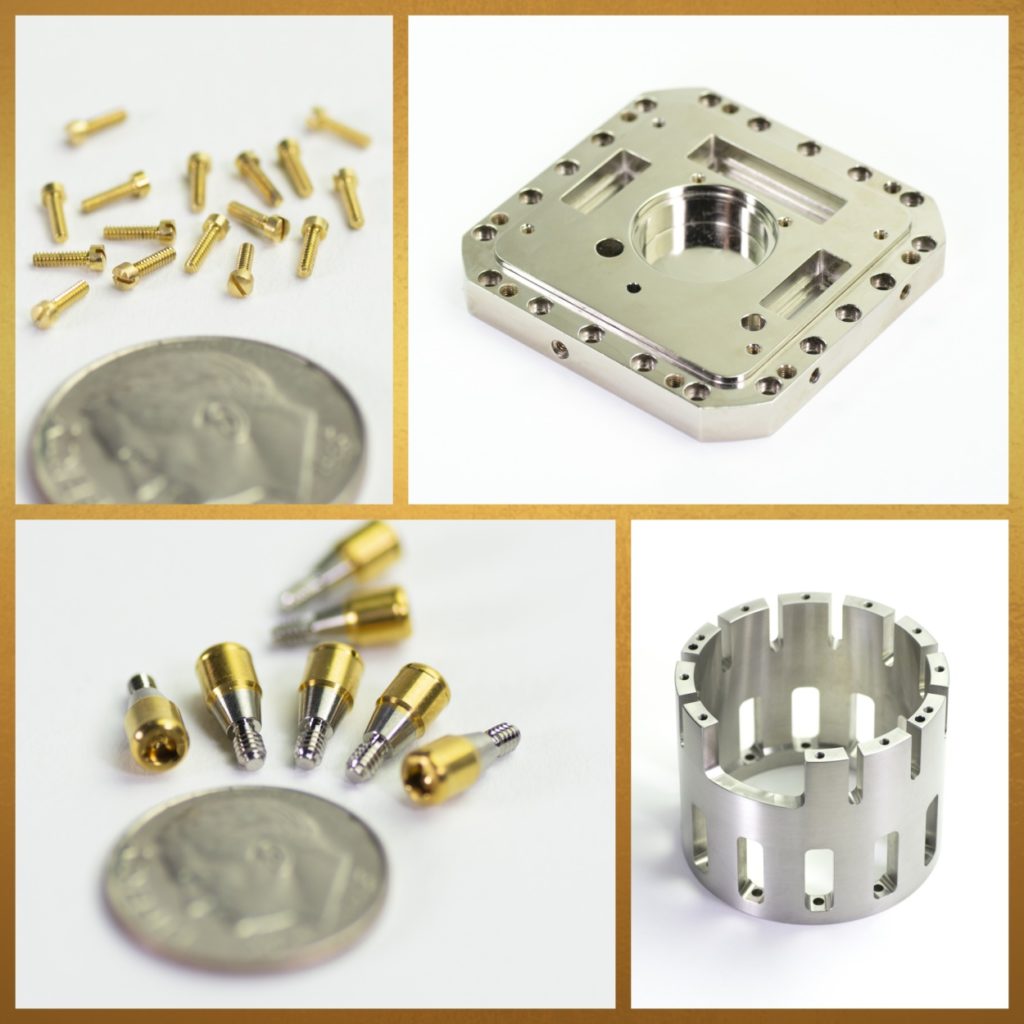

Masters of the Art of Swiss CNC Machining

For over 30 years, the craftsmen at Lindel CNC Machining and P4Swiss have provided their customers with unmatched precision and custom CNC machining. Since their merger in 2019, P4Swiss / Lindel team has excelled in production of Swiss and CNC machined parts to industries ranging from medical and optical to defense contractors, technology companies, aerospace and more. For customers requiring the highest in precision and craftsmanship, the P4Swiss / Lindel team takes Swiss CNC machining to a whole new level: With tolerances of less than +/- .001” and outside diameters (OD) measuring 1.25” or smaller. By exceeding the minimum tolerance

P4Swiss / Lindel Relaunches PrecisionCNCMachining.com with Updated Support

After the merger between Oceanside, California’s P4Swiss and Lindel CNC Machining from Tucson, Arizona, clients and prospects for both companies were notified of increased capabilities and location change. For much of the last year contact and communications strategies had been focused on building stronger standard operating procedures (SOP) and increasing service and support to our customers. As a final step to the service and support functions of the merger, a new, streamlined digital and Web presence with the new P4Swiss / Lindel CNC Machining brand mark has been relaunched under precisionCNCmachining.com. Beyond an updated logo, the restructured site has been

Critical Supplier Support From P4Swiss / Lindel CNC Machining

Virtually every release and news item seen out there these days focuses on the Coronavirus / COVID-19 Pandemic and how the shutdown of non-essential business has impacted the nation. While a large swath of the U.S. workforce has been sidelined from the virus, industries like medical manufacturing, military defense manufacturing, power generation, and others have stepped up to address the emergency. As Critical Suppliers to these industries, P4Swiss / Lindel CNC Manufacturing is working to increase production and reduce delivery times to assure we continue to serve the nation efficiently and effectively. While operations are far from “Business as usual,”

Dedicated Partners in Defense CNC Manufacturing

The P4Swiss / Lindel team has been part of some inspiring production and manufacturing programs. From custom engineered CNC machined parts sent into space to being an integral part of a high-precision CNC manufacturing supply chain, the precision CNC and Swiss CNC machining we do from our Tucson, Arizona plant makes the lives of our client-partner’s from around the nation better. If that wasn’t enough, we also provide custom CNC machined parts that go further than that. By partnering with U.S. Defense contractors and military manufacturers, the P4Swiss / Lindel team steps up to help defend our country and protect

Precision CNC Manufacturing From Tucson, Arizona to Space and Beyond!

The team at the Tucson, Arizona CNC machining company P4Swiss / Lindel have been looking skyward recently, and for good reason. Several precision CNC machined parts produced at the Tucson facility have been skyrocketing their way across the solar system documenting one particular asteroid 101955 Bennu, and they’re pretty proud of it. “Working with scientists and engineers at University of Arizona is always an exhilarating experience,” said Tom Ferrara, General Manager at P4Swiss / Lindel. “Being able to meet their design and engineering specifications and help with the production of OSIRIS-REx took real team effort.” CNC manufacturing for aeronautical parts

Precision 4 Swiss & Lindel CNC Machining- Looking Toward a Year of Opportunity

2019 is almost over, and what a whirlwind of a year! With the merger of Tucson Arizona’s Lindel CNC Machining and P4Swiss out of Oceanside, California, the capabilities of our new company for precision Swiss and CNC machining have expanded and exceeded even our own expectations. With new team members, new clients, evolving industries and the technology that drives it all, we’re seeing 2020 as “The Year of Opportunity” for our team… and yours! 2019 saw Lindel CNC Machining commit to growth and innovation. After almost a year with the new P4Swiss / Lindel team and our increased services and

CNC Market Buzz: How Will Smart Manufacturers Drive Into 2020?

If you’re like us, the end of the year means a lot of data collection, prospecting, and strategizing for the upcoming year. The predictable questions come up in production and sales meetings: How are 2019 sales? How do prospects look in 2020? Are customers buying more? Less? What about innovations? Diversification? How can we grow margins? And so on. At LINDEL CNC MACHINING and P4SWISS, the end of the year also means spending time in front of our market, attending trade shows, and listening to the “Market Buzz” from buyers and manufacturers on the floor. Through the end of October

It’s Q4 2019 How Will You Make an Impact in 2020?

As we close our Q3 and roll into Q4 of 2019, we’re working with our customers to build better industry knowledge, better industry service, and a stronger precision manufacturing future for us all. As an important part of our ongoing service to our customers, we’ve developed a quick, 3-minute survey to gather some of your perspective on today’s manufacturing business environment. By taking the P4Swiss / Lindel Engineering 2020 Customer Market Survey, you’ll provide much-needed insight to our industry, our products and services, as well as how to best serve you and our customers today and in the future. Please

Swiss CNC Machining is Now Offered at Lindel Engineering

In December 2018 Lindel purchased P4Swiss a Swiss CNC Machine company in San Diego. This past January we moved the company to our facility in Tucson. If you are looking for a high quality Swiss CNC Machined parts please sends us your requirements. We look forward to an opportunity to work with you.