The CNC Machining Process is widely used by manufacturers today. A CNC machine is highly beneficial and has a variety of advantages. The manufacturing process will perform a continuous and repeatable cutting procedure on raw material. CNC machinery is controlled and operated by a computer, so that it can manufacture a complex part. The History Behind CNC Manufacturing An idea that had been pondered over, for some time, was a numerical control (NC) perception of machining. A numerical control device was produced in the year 1949, by John Parsons. John was, otherwise, known as a computing pioneer. The Numerical Control

Read more about CNC machining in Tucson →Precision Machining a Nixie Tube Watch requires a complex, precise and advanced manufacturing process. A nixie tube watch is the solution to frustratingly short battery lives that the modern watches, today, have embodied. Here at P4Swiss/Lindel CNC Machining, we recently received the unique opportunity to manufacture watch housing components. Our team of mechanists effectively produced, both, round and square watch housing case units that have a high level of strength and durability, particularly fabricated for the Nixie Tube Watch. Precision Machining The Original Round Nixie Tube Watch A round Cathode Nixie Tube Watch was brought to light by a man

Read more about CNC machining in Tucson →Why commit to a precise 5-Axis CNC Milling machine for complex Defense Components? No attention to detail can be spared when it comes to Defense CNC Machining. P4Swiss / Lindel Engineering is the go-to choice among the many manufacturers who are currently fabricating defense equipment and tools. Our experienced and highly skilled machinists greatly excel in the craft of CNC milling, specifically 5-Axis CNC milling. Our machine shop can efficiently work with various materials that range from stainless steel all the way to titanium. CNC Machining For The Defense Industry When a Defense Component is machined for the Defense Industry,

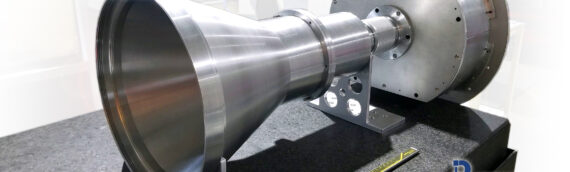

Read more about CNC machining in Tucson →The P4Swiss / Lindel team takes great pride in their precision CNC machining and the high-quality products we produce for our customers. Most pieces are quite small, requiring tolerances as tight as .0005”. Occasionally, though, customers come to us with requests for machining of larger, yet still highly complex parts. In a recent project, we were able to help with one such piece. “While the process is much the same, large, complex machined parts like this are a welcome challenge for our machinists,” said Tom Ferrara, P4Swiss / Lindel General Manager. This custom machined piece consisted of more than 40

Read more about CNC machining in Tucson →The team at P4Swiss / Lindel Precision CNC Machining has been navigating recent COVID-19 updates with special attention. While many manufacturers are focusing on a return-to-work strategy, the P4Swiss / Lindel team continues production and service at 100%, focused on serving their precision CNC manufacturing clients. While, as an industry, they’ve experienced a brief respite in business closures and slowed demand due to COVID, the need for precision medical supplies and custom, complex parts remains high. As a critical supplier to the medical industry, as well as others, they’re prepared to assist their customers through any additional pandemic issues that

Read more about CNC machining in Tucson →2019 is almost over, and what a whirlwind of a year! With the merger of Tucson Arizona’s Lindel CNC Machining and P4Swiss out of Oceanside, California, the capabilities of our new company for precision Swiss and CNC machining have expanded and exceeded even our own expectations. With new team members, new clients, evolving industries and the technology that drives it all, we’re seeing 2020 as “The Year of Opportunity” for our team… and yours! 2019 saw Lindel CNC Machining commit to growth and innovation. After almost a year with the new P4Swiss / Lindel team and our increased services and

Read more about CNC machining in Tucson →