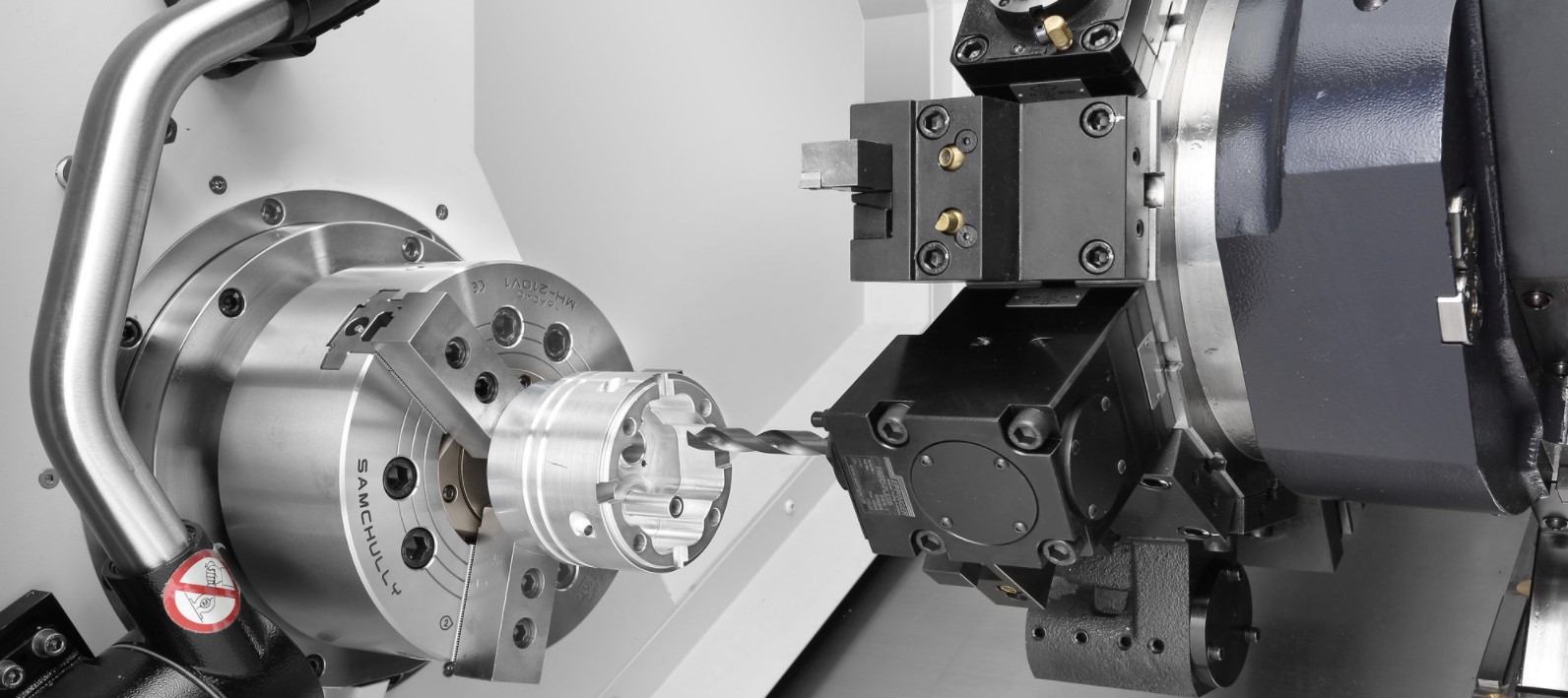

The CNC Machining Process is widely used by manufacturers today.

A CNC machine is highly beneficial and has a variety of advantages. The manufacturing process will perform a continuous and repeatable cutting procedure on raw material. CNC machinery is controlled and operated by a computer, so that it can manufacture a complex part.

Table of Contents

The History Behind CNC Manufacturing

An idea that had been pondered over, for some time, was a numerical control (NC) perception of machining.

A numerical control device was produced in the year 1949, by John Parsons. John was, otherwise, known as a computing pioneer. The Numerical Control (NC) concept was developed to carry out a research project for the Air Force. This research project took place at the Massachusetts Institute of Technology (MIT). The institute accommodated a Servomechanisms Laboratory that, essentially, anticipated building a milling machine. The goal was to, ultimately, utilize motorized axes, so that blades could be produced for helicopters, as well as frames and engines developed for aircraft.

By 1952, Richard Kegg was collaborating with the Massachusetts Institute of Technology (MIT). This teamwork resulted in a milling machine being successfully produced. This mill machine specifically operated with an eight column paper tape, a tape reader and a vacuum-tube control system.

In the 1940s and 1950s, punched tape was used in the machining process. Eventually, the punched tape technology was replaced with analog computing technologies. Once the 1960s and 1970s came around, digital technologies were available that provided an automated manufacturing process. Thus, making sure that CNC Machining became more efficient.

The CNC Machining Process Today

CNC Machines offer a Computer Numerical Control manufacturing technique.

The CNC Machining Process is an automated sequence of numerous machining procedures that are controlled with a computer. Since a computer controls the production process, various operations can be performed on a part simultaneously. Each procedure is going to be, entirely, dependent on the very same design.

CNC machinery will manufacture a part by precisely extracting material from a workpiece. The material is going to be subtracted with an automated motion of quality cutting tools. This machining technique is capable of manufacturing alongside numerous axes on a part, all at once. A CNC machine can ensure a highly accurate cutting process, due to a table that will move automatically, allowing the particular part to rotate. For that reason, the outcome of each individual product is going to be highly predictable with unbeatable results.

What Are The Advantages Of CNC Machining?

CNC machinery fabricates complex machined parts that have an intricate design.

CNC Machining Advantages:

- High precision & accuracy

- Thoroughly efficient & fast

- Accepts various materials

01) High Precision & Accuracy

Due to our advanced CNC machines, we can effectively manufacture products that come with an intricate design, properly producing the parts to their exact specifications.

CNC machinery, solely, relies on instructions from a computer, in order to manufacture parts. Because of this, the likelihood of an error transpiring during the production process can be removed. When the numerical control (NC) concept of machining was first established, errors would commonly occur on the machinery that was operated manually. Today, the CNC Machining Process can accurately fabricate complex machined parts, while precisely attaining a tight tolerance.

So what does accuracy, precision and tolerance mean for a machined part?

Accuracy is referred to as the proximity, or closeness, of the particular measurement to the part’s exact specifications. On the other hand, precision is known as the capacity of a measurement assessment, to repeatedly and continuously machine the very same specifications and design. In regard to tolerance, it is the acceptable amount of deviation that is followed, in the proportions and measurements of that part. Our machine shop greatly surpasses the minimum tolerance standards that are, generally, required from a lot of industries.

02) Thoroughly Efficient & Fast

In the traditional machining process, an operator was frequently required. An operator would have to manually alternate the specific cutting tools that were used in the production process. These cutting tools, ultimately, depended on the cutting procedure that was to be performed. This is a drawn out machining operation that is time consuming. Not only that, it is additionally inefficient. A manufacturing process that does not accommodate computerized control would, generally, result in an operator being the judge of your part’s end results.

The CNC Machining Process, today, features a rotating table that can support and leverage numerous tools. These tools have the ability to automatically interchange during the multiple manufacturing procedures. Therefore, a CNC machine will be able to provide fast and efficient cutting operations.

03) Accepts Various Materials

There are several materials available to choose from, when manufacturing with a CNC machine. In addition to that, CNC machinery can also produce a wide variety of products. Our machine shop particularly specializes in manufacturing non ferrous materials, exotic materials and machinable plastics.

Non Ferrous & Exotic Materials:

- Aluminum

- Copper

- Bronze

- Brass

- Titanium

- Stainless Steel

- Teflon

Machinable Plastics:

- Delrin

- Noryl

- Peek

- PVC

- UHMW

High Quality CNC Machined Parts

P4Swiss | Lindel CNC Machining can offer you an all around improved experience on your CNC manufacturing project. The machined parts that we fabricate are utilized in a wide range of products, across various industries. We regularly exceed the expectations of many industries – such as Medical CNC Machining, Aerospace CNC Machining, Optical CNC Machining and Defense CNC Machining. As a result, we have the capability to provide your industry with quality, high performance products.

Our machine shop can guarantee a shorter turn time experience, producing highly detailed machined parts. We use our technical support, breadth of knowledge and extensive experience to make sure that we provide our customers with full support, throughout the entire manufacturing process. With our advanced CNC machining technique, we can successfully produce intricately designed, complex products. Our skilled team manufactures at a higher level of precision and accuracy, surpassing standard CNC machine shops.

If you have any questions or would like to submit your own custom CNC RFQ, please do not hesitate to contact Tony Torrez at tony@p4swisslindel.com, call us at 520.792.3160 or click the “Request A Custom CNC Quote Today” button below.