Choosing the right CNC shop is crucial for any project that involves CNC manufacturing.

Whether you're in the aerospace, medical, optical or defense industry, the quality of CNC machining can significantly influence the final product.

Here are some key factors to consider when selecting the right CNC machine shop to ensure your projects are successful and your parts are manufactured to the highest standards.

Table of Contents

1. Experience and Expertise

When you're delving into the realm of CNC machining for your projects, understanding the experience and expertise of a CNC shop is crucial.

Here's a detailed look at why experience and expertise matter and how you can evaluate these factors when choosing the right CNC shop.

Understanding the Experience of a CNC Shop

Years in Business: Generally, a CNC shop that has been in business for many years is likely to have acquired a wealth of experience and a deep understanding of CNC manufacturing processes. Longevity in the industry often correlates with stability and reliability.

Diverse Project Portfolio: Experience should also be measured by the variety of projects a shop has undertaken. A CNC shop that has worked across diverse sectors — like aerospace, medical, optical and defense — will bring a versatile skill set and a proven track record of adapting to different industry standards and challenges.

Evaluating the Expertise of a CNC Shop

Specialized Knowledge: The expertise of a CNC shop refers to the specialized knowledge in particular areas of CNC machining. For instance, some shops may excel in 5-axis machining or have specialized capabilities in ultra-precision manufacturing. Depending on your project's specific requirements, you may need a shop with specialized skills.

Technical Expertise: Machinists and engineers with technical expertise are the backbone of any reputable CNC shop. Their ability to foresee potential issues in the production phase can save time and resources.

Asking the Right Questions

When you evaluate a CNC shop's experience and expertise, consider asking the following questions:

- How many years have you been in the CNC machining business?

- Can you provide examples of projects you’ve completed in my industry?

- What qualifications do your machinists and engineers hold?

- Do you have experience with the specific type of CNC machining required for my project?

A CNC machine shop with extensive experience will have a proven track record of handling diverse projects and overcoming complex manufacturing challenges. Not only that, but a shop that has successfully operated over a long period of time likely has the expertise to handle intricate CNC manufacturing processes and will be able to advise you on the best approaches for your project.

2. Technology and Equipment

The capabilities of the CNC machines in use can significantly impact the efficiency, precision, quality and types of products a shop can produce.

Advanced CNC machines, such as 5-axis machinery, can produce complex parts with high precision and in shorter time frames.

Here's a closer look at the various aspects of technology and equipment you should consider when choosing a CNC machine shop.

Types of CNC Machines

CNC Milling Machines

CNC milling machines are perhaps the most common type of CNC machinery.

A CNC mill machine comes in several configurations, which includes:

- 3-axis mills

- 4-axis mills

- 5-axis mills

- 7-axis mills

The more axes a machine has, the more complex parts it can create without the need to reposition the workpiece.

This type of machining is particularly important for parts that have intricate geometries or where tight tolerances are critical.

CNC Lathes or Turning Centers

CNC lathes or turning centers are primarily used for producing parts with cylindrical profiles.

Advanced CNC lathes feature live tooling capabilities, ultimately allowing the machine to perform milling operations during the turning process.

Swiss CNC Machines

In the world of precision manufacturing, Swiss CNC Machining has emerged as one of the most accurate methods for producing small and complicated components without any errors.

Swiss CNC machining, which is also referred to as Swiss turning, represents a specialized branch of CNC (Computer Numerical Control) machining.

Unlike traditional CNC machines, Swiss machines feature a unique design where the workpiece rotates within a guide bushing while the cutting tools move along its length. This setup not only minimizes vibration, but also ensures exceptional precision, making Swiss machining ideal for producing small, intricate components.

3. Quality Control

Quality assurance is paramount in CNC manufacturing, as it directly impacts the reliability and performance of the machined parts.

It’s important that you check the CNC shop's quality certifications, such as ISO 9001 or AS9100, which are indicators of reliable processes.

P4Swiss | Lindel CNC Machining is properly certified and ITAR compliant. Our facility performs process monitoring practices that strictly follow the ISO 9001 and AS9100 standards.

Effective quality control processes ensure that the parts produced meet the required specifications and standards, which is crucial for maintaining the integrity and safety of the final products.

Here's a detailed exploration of what to consider in terms of quality control when choosing a CNC shop.

Understanding Quality Certifications

ISO 9001 Certification: A CNC shop with ISO 9001 certification demonstrates its ability to consistently provide products and services that meet customer and regulatory requirements.

AS9100 Certification: Specifically designed for the aerospace industry, AS9100 includes all the elements of ISO 9001, but with additional requirements specific to aerospace. This certification is crucial for CNC shops serving the aerospace sector.

Final Quality Assurance

Final Inspection: Before the parts leave the shop, a final inspection should be conducted to ensure that they meet all the specifications and tolerances set by the customer. This final check minimizes the risk of defective or non-conforming parts reaching the customer.

4. Capabilities and Services Offered

Types of CNC Machining and Services

Different CNC shops might offer different types of machining, such as milling, turning, drilling or Swiss screw machining. Some might even offer additional services like our facility, such as:

- CAM Modeling

- Prototyping

- Assembly

- Finishing Services

Material Specialization

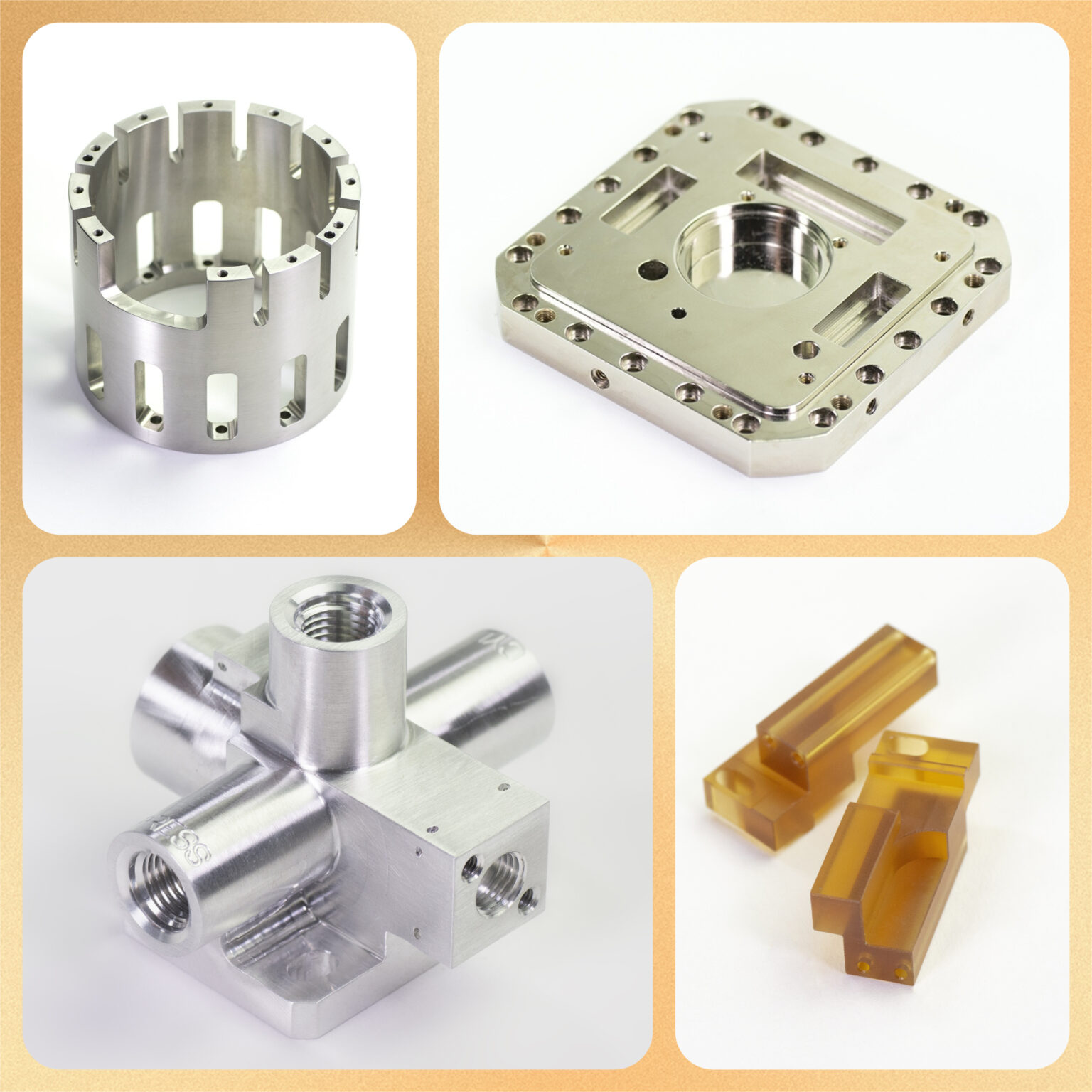

Some CNC shops specialize in specific materials or have extensive experience with a broad range of materials. This could range from common metals like aluminum and steel to exotic alloys and plastics.

Make sure the shop you choose has the ability to work with the materials required for your projects, especially if they involve unique or challenging materials.

However, a shop that’s well-versed in a variety of materials will be able to provide valuable insights and suggestions on material selection and treatment to enhance the durability and performance of your finished parts.

P4Swiss | Lindel CNC Machining can manufacture a variety of substances. Our facility specializes in non-ferrous and exotic materials like:

- Aluminum

- Copper

- Bronze

- Brass

- Titanium

- TeflonR

- Red Metals

- Plastics

- Stainless Steel

Consider what services you need and choose a CNC shop that can handle all aspects of your project under one roof, like we can at P4Swiss | Lindel CNC Machining. This can reduce logistics complexity, shorten lead times and potentially lower costs.

5. Reputation and Reviews

When it comes to selecting a CNC shop, reputation and reviews are often indicative of the reliability, quality and customer satisfaction associated with their services.

A strong reputation can be a deciding factor, providing a sense of security and trust in the shop's ability to deliver high-quality products and services consistently.

Assessing Reputation

Longevity in the Market: How long a shop has been in business can tell you a lot about its stability and experience. Long-standing operations are likely to have refined their processes over time and are typically more reliable.

Leveraging Reviews

Testimonials: Positive reviews and customer testimonials from previous clients can provide a glimpse into the shop’s reliability, quality of work and customer service.

Choosing the Right CNC Shop

Selecting the right CNC shop is a decision that requires careful consideration of many factors. It’s important that you choose a CNC machine shop that can meet your needs and exceed your expectations.

Remember, the right CNC partner not only ensures the success of your current project, but can also become a valuable asset for future endeavors.

If you have any questions or would like to submit your own custom CNC request for quote (RFQ), please do not hesitate to contact Tony Torrez at tony@p4swisslindel.com, call us at 520.792.3160 or click the “Request A Custom CNC Quote Today” button below.