In the dynamic landscape of precision manufacturing, the recent acquisition of Western Automatic Machining, Inc. by our company P4Swiss/Lindel CNC Machining marks a significant milestone.

As a leader in CNC manufacturing services, our company’s expansion in Tucson, Arizona is not just about growing our footprint - it’s about merging expertise, technology and capability to deliver unparalleled precision and quality in machining services.

A Strategic Move For Enhanced Capabilities

In November 2023, P4Swiss/Lindel CNC Machining acquired a company that’s renowned for its precision machining services - Western Automatic Machining, Inc.

"I have chosen to sell Western to P4Swiss/Lindel because I believe they are the right company to carry on the legacy of this business", says Kevin Pierce (former President of Western Automatic Machining, Inc.). "Their goal is to continue providing the same quality and on-time delivery that our customers are accustomed to, as well as maintaining competitive price points."

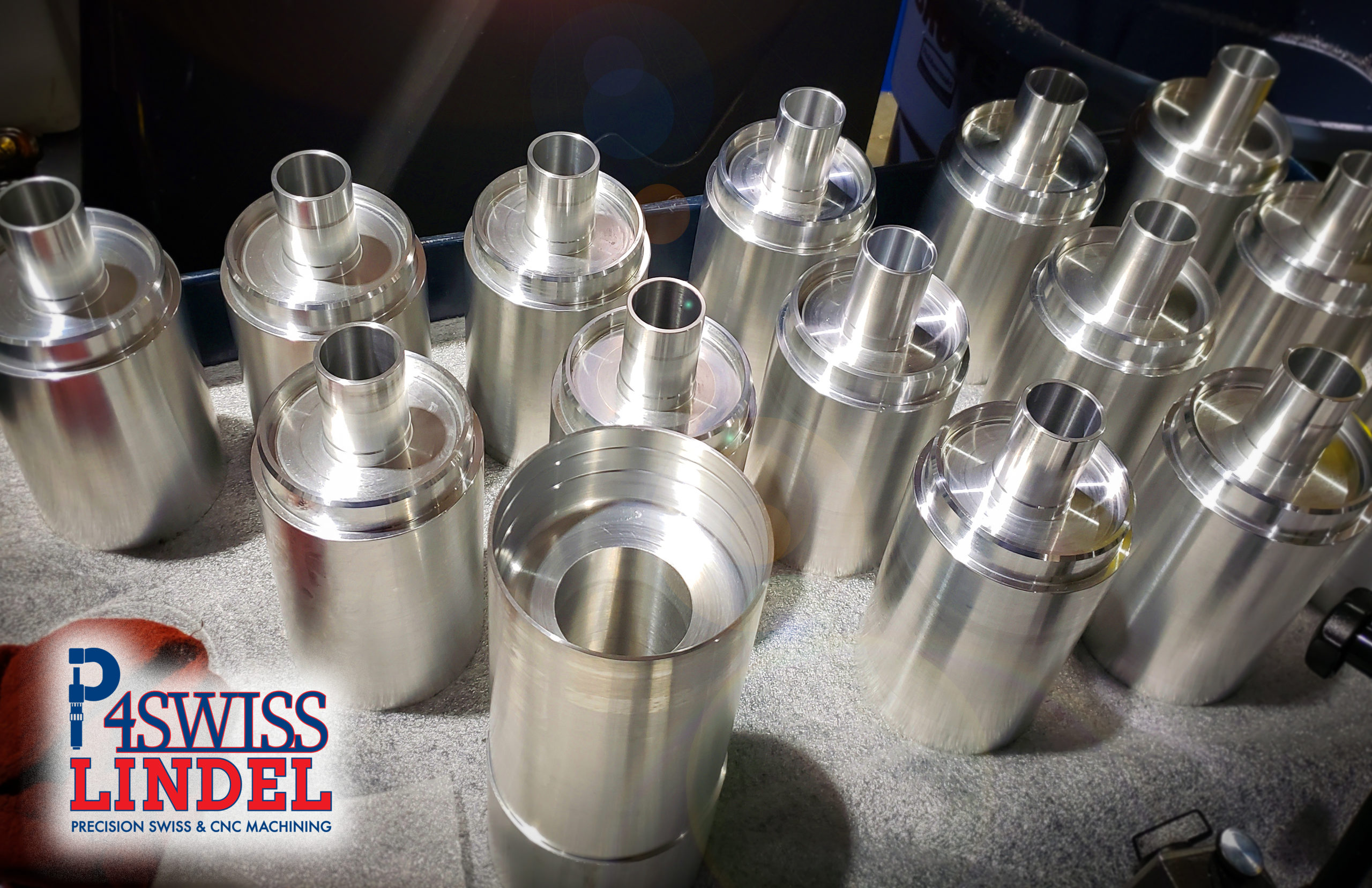

![[image 1] acquisition blog [image 1] acquisition blog](https://precisioncncmachining.com/wp-content/uploads/2024/02/image-1-acquisition-blog.jpeg)

This acquisition is a game-changer, combining our expertise and skills with Western Automatic Machining’s knowledge and capabilities.

P4Swiss/Lindel CNC Machining’s Capabilities:

- CNC Turning

- Swiss CNC Screw Machining

- 3-Axis CNC Milling

- 4-Axis CNC Milling

- 5-Axis CNC Milling

Western Automatic Machining’s Capabilities:

- 7-Axis CNC Milling

- Swiss CNC Screw Machining

- Precision Automatic Machining

- Milling

- Cross Drilling

Comprehensive CNC Manufacturing Under One Roof

With this acquisition, our facility is now able to offer a comprehensive range of manufacturing services.

Our enhanced capabilities enable our clients to have access to a wider variety of machining options, ranging from intricate Swiss CNC screw machining to complex 7-axis machining, all under one roof. For that reason, P4Swiss/Lindel CNC Machining stands as a powerhouse in the precision machining industry.

The acquisition has allowed us to expand our Swiss department by 200%. Our facility went from having 4 Swiss machines to 12 Swiss machines. The new Swiss machinery provides 7-axis machining, which we did not previously offer, ultimately giving us more capability. Not only that, but the 200% growth has also given our business much more capacity, as well.

This integration translates to increased efficiency, faster turnaround times and a level of precision that is hard to match.

Swiss CNC Screw Machining

Swiss CNC screw machining has emerged as one of the most accurate methods for producing small, complicated components without any errors. As a result, this process is ideal for manufacturing the precise parts that are often required in medical devices and electronic hardware.

A Swiss CNC Machine:

- Excels with small diameter parts

- Ensures continuous & repeatable results

- Offers versatility & flexibility

With the merger, we now have more Swiss machines that offer these specialized services, giving us the ability to fully cater to industries where precision is paramount.

3-Axis, 4-Axis, 5-Axis & 7-Axis Machining

With the acquisition of Western Automatic Machining, we now have a full spectrum of CNC capabilities.

In the world of CNC (Computer Numerical Control) machining, the terms 3-Axis, 4-Axis, 5-Axis and 7-Axis refer to the number of directions in which the cutting tool can move. Each axis represents a different dimension of motion, essentially allowing for more complex and precise cuts.

Let’s break down what each of these capabilities means.

![[image 2] acquisition blog [image 2] acquisition blog](https://precisioncncmachining.com/wp-content/uploads/2024/02/image-2-acquisition-blog.jpeg)

3-Axis CNC Machining: The Foundation

3-axis machines are the most basic and common type.

In 3-axis CNC Machining, the cutting tool moves along the X, Y and Z axes. This manufacturing process allows for operations like drilling, milling and tapping.

3-Axis machines are perfect for parts that don't require complex geometries or intricate detailing. With that being said, this machinery is typically ideal for creating flat or basic curved surfaces and is often used for automotive parts, basic moldings and enclosures.

4-Axis CNC Machining: Adding Flexibility

Stepping up the complexity, 4-Axis CNC Machining introduces an additional rotational axis.

Besides moving up and down, left and right, and back and forth, the workpiece can also rotate around the X-axis (often referred to as the A-axis). This added flexibility allows for machining on the sides of a workpiece, creating more complex shapes.

5-Axis CNC Machining: Complex & Precise

5-Axis CNC machining further increases precision and complexity.

In addition to the movements performed by 3-axis and 4-axis machines, the cutting tool on a 5-axis CNC machine can move across two additional rotational axes (usually the A-axis and B-axis). This ability means that the tool can approach the workpiece from any direction.

5-Axis machining is essential for aerospace components, intricate molds and complex medical devices, as it can create sophisticated shapes with high precision.

7-Axis CNC Machining: The Pinnacle Of Versatility

7-Axis CNC machining represents the pinnacle of machining versatility and complexity.

A 7-axis machine includes all the capabilities of the 5-axis machine, but with two additional axes. These additional axes allow for simultaneous machining with multiple tools, drastically reducing production time and increasing efficiency.

This manufacturing technique is used in highly specialized applications that require extreme precision and multitasking, like advanced aerospace and military components.

![[p4swiss-lindel] CNC_Manufacturing [p4swiss-lindel] CNC_Manufacturing](https://precisioncncmachining.com/wp-content/uploads/2024/01/p4swiss-lindel-CNC_Manufacturing.jpg)

The Many Advantages Of Combined Expertise

Understanding the differences between these types of CNC machining operations is crucial when selecting the right process for your project.

Each type offers different advantages:

3-axis: simplicity & cost-effectiveness for basic shapes.

4-axis: enhanced flexibility for more complex parts.

5-axis: high precision for creating complex geometries.

7-axis: ultimate versatility for advanced applications.

This diversity ensures that no matter the complexity or precision required, we have the technology and expertise to deliver outstanding results.

Meeting The Growing Demand With Advanced Technology

The demand for high-precision machined components is on the rise, fueled by advancements in sectors such as aerospace, medical, automotive and defense.

Here at P4Swiss/Lindel CNC Machining, our facility is well-positioned to successfully meet these growing demands, due to the combined force of our company and Western Automatic Machining.

The state-of-the-art technology that’s utilized in 7-axis and 5-axis machining allows for the production of complex geometries with high precision, which is essential for the components that are used in critical applications.

A Commitment To Quality & Customer Satisfaction

Quality has always been at the heart of P4Swiss/Lindel CNC Machining’s operations.

This acquisition reinforces our commitment to providing top-notch products. By integrating Western Automatic Machining’s advanced machinery and quality control processes, we can ensure that each component will always meet the highest standards of precision and quality.

The Future Of Manufacturing: Agile, Advanced & Customer-Centric

Looking ahead, our company is set to redefine the standards in CNC Machining.

Our approach is agile, adapting to the changing needs of the industries that we serve - such as:

The expanded capabilities means that we can take on more complex and varied projects, pushing the boundaries of what’s possible in CNC machining.

Tailored Solutions For Diverse Industry Needs

With a diverse range of machining options now available, P4Swiss/Lindel CNC Machining can offer you more tailored solutions.

Whether it’s a custom part for a medical device, a critical component for an aerospace application or high-volume production, our machine shop has the technology, machinery and expertise to deliver.

Enhancing Supply Chain Reliability

In today’s fast-paced world, reliability is key.

The acquisition strengthens our facility’s supply chain, ensuring that our customers receive their products on time and to specification. This reliability is crucial for the companies who operate in industries where delays can have significant repercussions.

A New Chapter Of Excellence In CNC Machining

The acquisition of Western Automatic Machining by P4Swiss/Lindel CNC Machining is more than just a business expansion - it’s the beginning of a new chapter in the field of precision machining.

You now have access to a wider range of top-quality machining services here at our machine shop, backed by a team of experts dedicated to meeting and exceeding your expectations.

If you have any questions or would like to submit your own custom CNC request for quote (RFQ), please do not hesitate to contact Tony Torrez at tony@p4swisslindel.com, call us at (520) 792-3160 or click the “Request A Custom CNC Quote Today” button below.