Table of Contents

CNC Mill Machines allow us to efficiently manufacture small, complex and precise CNC machined parts.

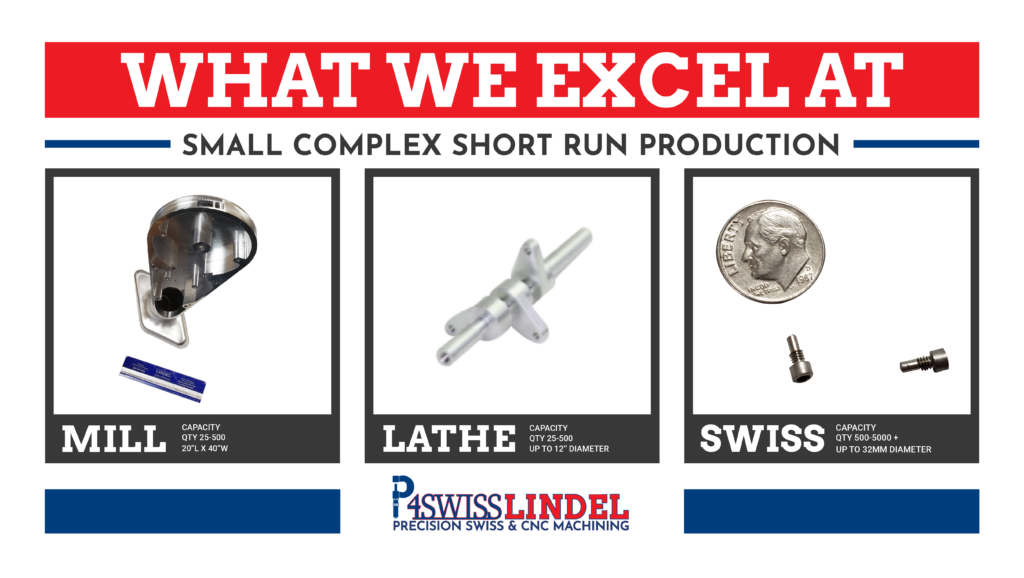

What We Excel At

At P4Swiss/Lindel, our quality team excels at small complex short run production. We not only have 3-axis and 4-axis machining, but 5-axis CNC mill machines, as well.

There are some CNC machine shops that will only manufacture with 3-axis or 4-axis CNC machining. Here at P4Swiss/Lindel, we efficiently utilize the advanced 5-axis CNC milling machines. As a result, we can provide our customers a shorter turn time experience. We are, also, able to offer completed mill runs from 25 to 500 pieces more quickly and more precise than other CNC machine shops.

We have three dedicated 5-axis milling machines with work envelopes that range up to 12 inches in diameter. One of our CNC mill machine's work envelope specifically measures to 20”L x 40”W. Our advanced CNC machining offers higher quality on intricately designed pieces, providing a higher level of milling precision that surpasses standard CNC machine shops.

CNC Mills & Multi-Axis Lathes

With a wide selection of production levels, we have lathes that produce some of the country’s most precise and small, complex parts. Our highly qualified team took giant strides in precision, offering the companies we do business with multi-axis lathes for CNC machining. We are able to efficiently keep up with demand utilizing our Doosan Puma 2100SY lathe.

Benefits of the Doosan Puma 2100SY lathe:

- High performing

- Specialized in precision CNC production

- Specialized in premium surface finishes

This machine can take on some of the toughest materials. The Doosan Puma 2100SY lathe can effectively manufacture titanium alloys, steel, aluminum and more. Our highly precise lathe has expanded our CNC Lathe department and Swiss CNC machining abilities. As a result, ensuring that the accurate and integrated y-axis improves productivity, guiding each precision part from beginning to end.

Swiss CNC Machining Improves Productivity

P4Swiss/Lindel offers Swiss CNC machining, providing expertise when defense contractors or the medical industry needs dependable, precision machined parts. We have the capability to constantly manufacture quality, complex CNC machined parts. Thus, allowing our team of industry professionals to support a wide range of vital industries.

We can produce orders of 500 to 5000+ Swiss units. Our CNC machine shop's turn times have decreased to 2 to 3 weeks. We have efficiently expanded our Swiss CNC machining abilities, with a $50,000 microscope. This microscope is necessary to verify the tight tolerance that is required for highly qualified Swiss CNC machining.

Our Shop Offers Post-Machined Finishing In:

- Heat treating

- Anodizing

- Plating

Our advanced CNC machine shop is surpassing the minimum tolerance standards that are required from a lot of industries.

If you have a question or would like to submit your own custom CNC or Swiss CNC RFQ, please reach out to Tony Torrez at tony@lindelengineering.com, call us at 520.792.3160 or click the button below.

We look forward to working with you!