In the world of precision manufacturing, Swiss CNC Machining has emerged as one of the most accurate methods for producing small and complicated components without any errors.

In recent years, there has been a significant growth in fabricators deciding on a Swiss CNC machine to manufacture the parts, tools and equipment that are needed in their facility’s production operations. The increase in demand for Swiss CNC machined parts has enabled this advanced manufacturing process to attain widespread recognition and popularity among a wide variety of industries.

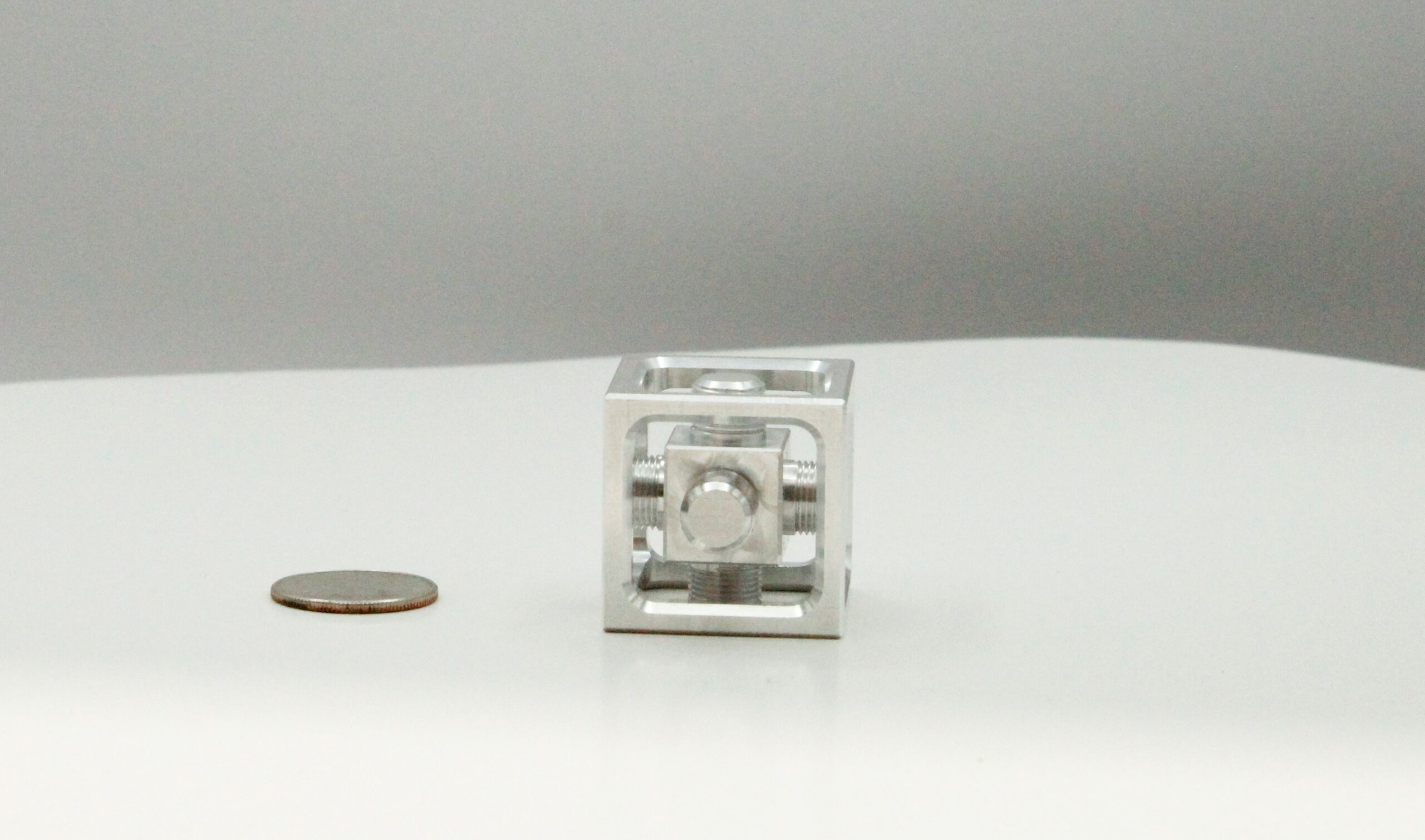

Here at P4Swiss | Lindel CNC Machining, we recently received the opportunity to produce a precision machined, enclosed cube. This Swiss CNC machined part has 6-post Fitting Junction Coupler Adapters that are manufactured on the inside. To successfully fabricate this unique and precise component, Swiss CNC machinery was necessary.

The History Of Swiss CNC Machining

Swiss CNC Machining was invented in Switzerland.

In the 1800s, the machining industry desperately needed a solution that would allow them to produce very small machined parts. In addition to that, they needed a manufacturing process that was able to securely support small and complex parts throughout the operation.

A man by the name of Jakob Schweizer had the advanced idea to glide a part down the longitudinal axis of a lathe, rather than the tool sliding along a part like the traditional lathes operate. He, additionally, envisioned that the part would be supported by a turning headstock, while it transfers the part through a guide bushing. This will, ultimately, enable a fully secure machining procedure. With this machinery, turning tools have the ability to perform the manufacturing operations in an extremely close proximity to the supporting collet. As a result, a highly accurate cutting technique is guaranteed.

Today, CNC controllers have been incorporated in Swiss CNC machines to efficiently automate a repeated manufacturing process.

Understanding Swiss CNC Machines

A Swiss CNC machine, which is also known as a Swiss-type lathe, has a specialized form of CNC (Computer Numerical Control) machining. This manufacturing technique, particularly, excels in producing small and complex machined parts.

The traditional CNC machining process, typically, operates on a part that is being held in a stationary position. However, Swiss CNC machining entails a unique design that enables the part to move along the longitudinal axis, while the cutting tool stays stationary. A sliding headstock and a guide bushing are both required to perform this operation. The guide bushing is going to support and guide the part, as it is being fed through a spindle that is rotating. This will result in exceptional stability, precision and accuracy during the machining process.

Advantages Of A Swiss CNC Machine

1. Exceptionally High Precision

Swiss CNC machining is renowned for delivering outstanding precision and accuracy. The Swiss CNC machine's sliding headstock and guide bushing are going to guarantee excellent stability. Not only that, but this manufacturing procedure minimizes vibrations, ensuring a precise machining process. With the level of precision that is provided in Swiss CNC machining, tight tolerances and intricate geometries are successfully manufactured, providing superior accuracy and surface finish.

2. Excels With Small Diameter Parts

Swiss CNC machines greatly excel at handling the workpieces that contain a small-diameter. The guide bushing is able to offer optimal support that is notably close to the cutting area. This is going to reduce deflection, while enabling slender components to be fabricated with remarkable accuracy. The capability of this machinery is specifically valuable in industries where complex and tiny parts are prevalent, such as medical, aerospace, optical and defense.

3. Generates Less Material Waste

Swiss CNC machining is known for its efficiency in material utilization, by minimizing the material waste. The guide bushing is going to secure the part, so that material vibrations and flexing are both minimized during the machining process. If less material is being wasted, increased productivity is assured.

4. Simultaneous Operations With Increased Productivity

Swiss CNC machines will, oftentimes, feature various tooling stations. Multiple tooling stations are going to allow for simultaneous machining operations. This means that different tools are able to simultaneously work on different parts of a workpiece. As a result, cycle times will be reduced and productivity will be enhanced. With simultaneous operations, complex parts can be completed in one individual setup, which will reduce the need for additional handling and improve the overall efficiency of the process.

5. Flexibility and Versatility

A Swiss CNC machine offers versatility, specifically in terms of the range of materials that it can handle. This machinery has the ability to effectively produce exotic materials, such as metals, plastics and composites. With that being said, it is well suited for a diverse range of applications across various industries. Not only that, but these machines can also perform a wide range of operations. They are adaptable to all different types of manufacturing requirements.

6. Continuous and Repeatable Results

The computer numerically controlled nature of Swiss CNC machining ensures continuous and repeatable results. A Swiss CNC machine is programmed with certain desired specifications, so that it can continuously replicate the exact same machining procedures. The variations that can be caused by human error can, then, be eliminated. This level of consistency is vital in industries that require the highest quality and reliability.

7. Cost-Effective for High-Volume Production

A Swiss CNC machine excels in the high volume production runs. This machining process is cost effective for large scale manufacturing, due to the combination of:

- Simultaneous operations

- Reduced material waste

- Efficient cycle times

With the ability to produce precise and intricate parts at a faster rate, increased production efficiency and improved profitability are guaranteed.

Applications of Swiss CNC Machining

Swiss CNC machining is used for various applications in a wide range of industries. Some of the most common sectors that can benefit from this process are:

Medical Industry

Swiss CNC machining is widely used in the medical industry, specifically for producing surgical instruments and other critical components that require exceptional precision.

Aerospace Industry

Swiss CNC machining, in the aerospace sector, is employed to manufacture components that require high precision, strength and reliability - such as fuel system parts, hydraulic fittings and landing gear parts.

Optical Industry

Swiss CNC machines are able to precisely manufacture tight tolerances for the optical industry. This process has the ability to properly produce small and complex parts that have precise optical properties - like lenses and prisms.

Defense Industry

There is a critical nature of military applications. Therefore, the defense industry is subject to significantly strict quality standards. Swiss CNC machining offers a highly efficient way to produce the long slender components that are used in military rifles - such as dust cover pins and firing pins.

Swiss CNC Machining

The Swiss CNC machine offers an incredibly precise and efficient manufacturing process. This manufacturing technique is capable of fabricating highly intricate parts with exceptional accuracy.

With the continuous advancement of technology, Swiss CNC machining is able to constantly evolve. As a result, the boundaries of precision manufacturing continue to be pushed, which ultimately enables the creation of increasingly complex components.

If you have any questions or you would like to submit your own CNC request for quote (RFQ), please do not hesitate to contact Tony Torrez at tony@p4swisslindel.com, call us at 520.792.3160 or click the “Request A Custom CNC Quote Today” button below.