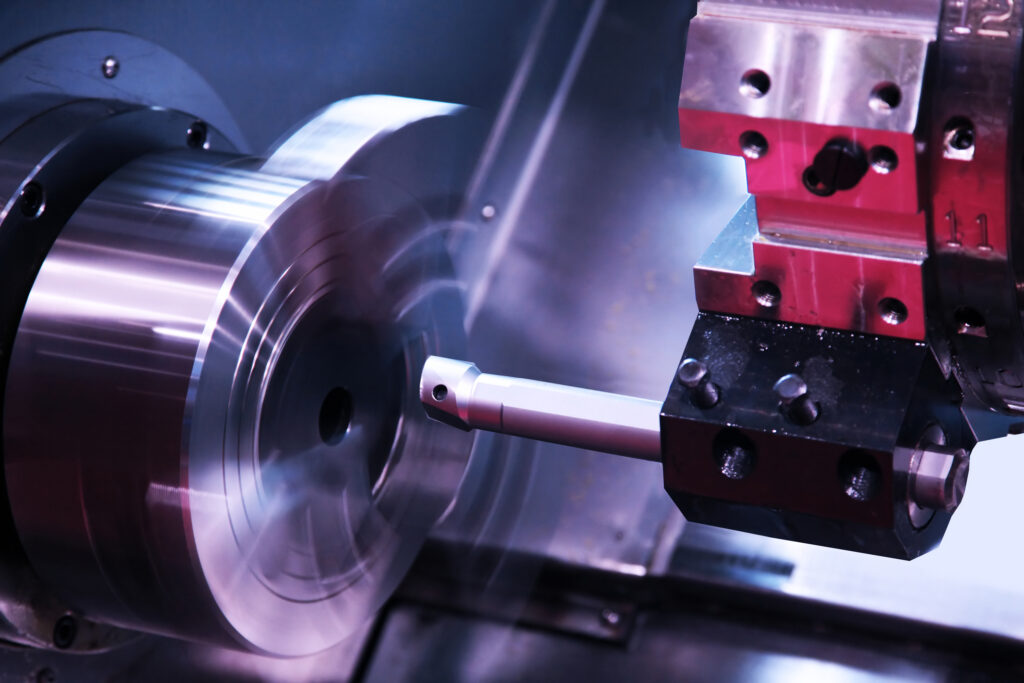

In today’s fast-paced and competitive manufacturing industry, precision and efficiency are more crucial than ever. As designs become more intricate and the demand for tighter tolerances continues to grow, traditional machining methods often fall short. This is where multi-axis machining comes into play.

Multi-axis machining has revolutionized how manufacturers produce complex components across industries like aerospace, medical, optical and defense. By enabling movement along more than the conventional three axes, this advanced technology makes it possible to create detailed, high-precision parts with greater speed and accuracy.

Table of Contents

In this blog post, we’ll explore what multi-axis machining is, how it works and why it has become an essential part of modern precision manufacturing.

What Is Multi-Axis Machining?

Multi-axis machining refers to a method in which computer-controlled tools move along multiple axes to shape and cut material. While traditional CNC machining operates along three linear axes (X, Y and Z), multi-axis machines introduce rotational movements, allowing for even more axes.

These additional axes allow the cutting tool to approach the workpiece from various angles without needing to reposition the part manually. This capability significantly enhances efficiency and precision, especially for complex geometries.

Types of Multi-Axis Machines

Understanding the different types of multi-axis machines helps highlight the benefits they offer for complex part production.

In the world of CNC machining, the terms 3-axis, 4-axis, 5-axis and 7-axis refer to the number of directions in which the cutting tool can move. Each axis represents a different dimension of motion, essentially allowing for more complex and precise cuts. Let’s break down what each of these capabilities mean.

3-Axis Machining

- Standard movement along X, Y and Z axes.

- The X-axis is a horizontal movement from left to right.

- The Y-axis is a horizontal movement from front to back.

- The Z-axis is a vertical movement that moves up and down.

- Ideal for simple shapes and flat surfaces.

4-Axis Machining

- Adds an additional rotational axis (A-axis).

- The A-axis rotates around the X-axis.

- Useful for creating holes and features on multiple sides of a part without manual repositioning.

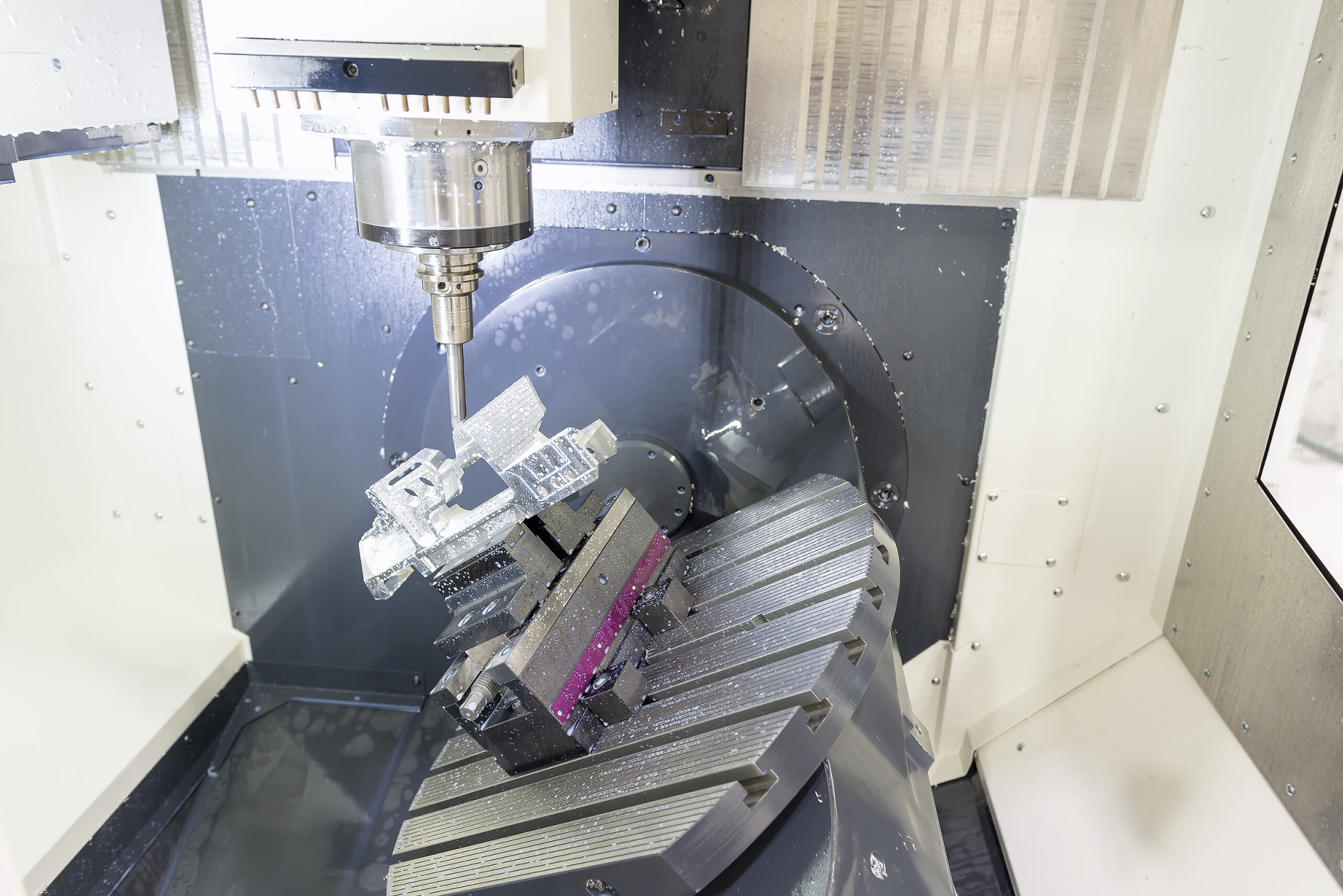

5-Axis Machining

- Adds additional rotation around two axes (A-axis and B-axis).

- The A-axis rotates around the X-axis.

- The B-axis rotates around the Y-axis.

- Enables the machining of extremely complex parts in a single setup.

7-Axis Machining

- Has all the capabilities of 5-axis machining, but with two additional axes.

- Used in highly specialized applications.

- Offers maximum flexibility and precision.

Advantages of Multi-Axis Machining

1. Enhanced Precision

With the ability to machine from multiple angles in a single setup, a multi-axis machine ensures tighter tolerances and higher accuracy. This is especially critical for components that must meet strict industry standards.

2. Greater Efficiency

Reducing the need to manually reposition a workpiece saves time and labor. Multi-axis machines can complete complex parts faster than traditional methods, improving overall production timelines.

3. Complex Geometries

Intricate designs, undercuts and contoured surfaces become feasible with a multi-axis machine. This capability is vital for industries requiring intricate parts, such as medical implants or aerospace components.

4. Reduced Setup Time

One of the biggest time-savers is the ability to machine all sides of a part without stopping to reset the material. This leads to fewer errors and higher throughput.

5. Improved Surface Finish

Fewer setups and uninterrupted machining contribute to a smoother surface finish, reducing the need for secondary operations like polishing or grinding.

6. Lower Risk of Human Error

Automated multi-axis systems minimize manual intervention, decreasing the chances of mistakes and improving consistency across production runs.

Why Multi-Axis Machines Matter for Complex Parts

As part complexity increases, so does the challenge of maintaining accuracy and meeting tight deadlines.

Multi-axis machines solve these challenges by enabling:

- Seamless transitions between multiple cutting paths

- More consistent part quality

- Efficient machining of parts with intricate contours or multiple features

Industry Applications of Multi-Axis Machining

Multi-axis machining is used in a wide range of industries that demand precision, durability and reliability:

Aerospace Industry

In the aerospace industry, aircraft components must meet exact specifications to ensure safety and performance. Multi-axis machines are ideal for creating:

- Structural components

- Turbine blades

- Brackets

Medical Industry

The medical industry requires biocompatible materials and tight tolerances. Multi-axis machining offers the ability to create:

- Surgical instruments

- Implants

- Diagnostic equipment parts

Defense Industry

High-performance materials and exact specifications are standard in defense machining. Multi-axis capabilities enable the production of:

- Weapon system components

- Communication devices

- Tactical equipment parts

Optical Industry

Precision is critical in the optical sector. Multi-axis machining is ideal for producing tiny, intricate parts used in instruments like microscopes, telescopes and cameras:

- Lens holders

- Alignment fixtures

- Instrument mounts

Material Compatibility

Multi-axis machining is versatile in the range of materials it can handle, including:

- Aluminum

- Titanium

- Stainless steel

- Brass

- Copper

- Bronze

- Teflon

- Plastics (Delrin®, PEEK, UHMW, PVC)

At P4Swiss / Lindel CNC Machining, we specialize in manufacturing non-ferrous and exotic materials with precision and consistency.

When Should You Use Multi-Axis Machining?

If your part:

- Has intricate or contoured features

- Requires tight tolerances

- Must be machined from multiple angles

- Needs to be completed in fewer setups

... then multi-axis machining is likely the most effective and efficient solution.

Multi-Axis Machining at P4Swiss / Lindel CNC Machining

At P4Swiss / Lindel CNC Machining, we utilize advanced multi-axis CNC machines to meet the complex needs of our clients across a wide range of industries. Our experienced team provides full support from design review and prototyping to delivery, working with your team to achieve the highest standards of quality and performance.

With over 30 years of experience, certifications in ISO 9001 and AS9100 and a commitment to machining excellence, we are equipped to handle your most challenging parts with confidence.

Making the Right Machining Choice

As the demand for high-precision, complex components continues to grow, so does the need for efficient, reliable machining solutions. Multi-axis machining not only meets these demands, but exceeds them — making it a cornerstone of modern manufacturing.

If you’re developing parts that require advanced capabilities, now is the time to consider the advantages of multi-axis machining.

Ready to Start Your Project?

Contact P4Swiss / Lindel CNC Machining to learn more about our multi-axis machining capabilities.

If you have any questions or would like to submit a CNC request for quote (RFQ), please do not hesitate to contact Tony Torrez at tony@p4swisslindel.com, call us at (520) 792-3160 or click the “Request a Custom CNC Quote Today” button below.