In the world of modern manufacturing, precision, efficiency and consistency are no longer optional — they are essential. When it comes to machining processes, CNC milling has become the gold standard, leaving traditional milling methods behind in many industries. While both techniques shape raw material into finished components, CNC milling offers a wide range of advantages that manufacturers, engineers and product designers rely on for producing high-quality parts.

In this blog post, we’ll dive into the differences between CNC milling and traditional milling, then explore the key benefits CNC milling provides across industries like aerospace, medical, defense and optical.

Table of Contents

Understanding CNC Milling vs. Traditional Milling

Before exploring the advantages of CNC milling, it’s important to understand how it differs from traditional milling.

- Traditional Milling: This process uses manually controlled machines operated by machinists. The operator adjusts tool movements, feed rates and part positioning by hand. While effective, it is highly dependent on the machinist’s skill, making it prone to human error and variations.

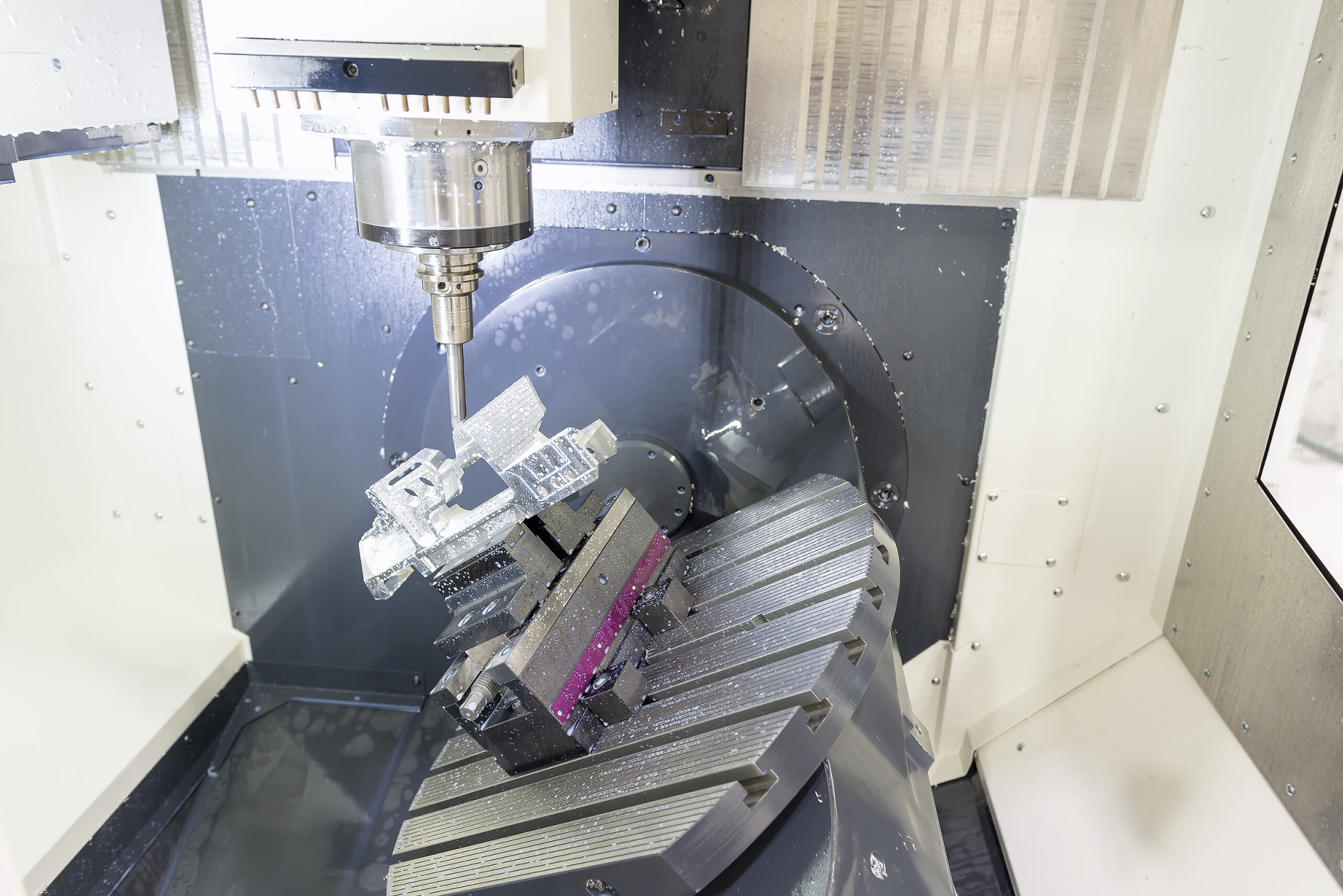

- CNC Milling: CNC stands for Computer Numerical Control. In CNC milling, machines are programmed using CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. Once the program is set, the machine automatically carries out cutting, drilling and shaping operations with remarkable accuracy and repeatability.

The automation of CNC machining minimizes manual input, increases productivity and allows for the creation of parts with far greater complexity than traditional milling can achieve.

Advantages of CNC Milling

1. Superior Precision and Accuracy

One of the most significant advantages of CNC milling over traditional milling is its ability to achieve exceptional precision. In industries like aerospace and medical, even the smallest error can compromise safety and functionality.

CNC milling machines can achieve tolerances within a few microns, something that’s nearly impossible to maintain consistently with manual machining. This level of precision ensures that every part meets exact specifications, whether it’s a one-off prototype or a full production run.

Traditional milling, by comparison, depends on the machinist’s ability to manually measure and cut. While skilled operators can produce accurate parts, human error remains a constant risk. CNC machining removes much of this variability.

2. Enhanced Repeatability

Manufacturers often require hundreds or thousands of identical parts. Traditional milling struggles to achieve this consistency because slight differences can occur from part to part due to manual handling.

With CNC milling, repeatability is virtually guaranteed. Once a program is created and validated, the machine can run the same operation as many times as needed, producing parts that are consistently accurate.

This repeatability is crucial in industries where uniformity ensures product reliability, such as medical implants.

3. Greater Efficiency and Productivity

Time is money in manufacturing, and CNC milling excels in both speed and efficiency.

- CNC machines can run continuously 24/7, with minimal supervision.

- They can perform multiple operations in one setup, reducing downtime caused by manual adjustments.

- Advanced CNC milling machines often feature automatic tool changers, which further increase efficiency by seamlessly switching between tools during the machining process.

Compared to traditional milling — where operators must frequently stop to adjust tools, reposition parts or check measurements — CNC milling drastically reduces production time.

4. Ability to Machine Complex Geometries

Product designs today often require intricate geometries and detailed features that are beyond the capabilities of traditional milling machines.

CNC milling machines, especially multi-axis models, can handle these complex designs with ease. They allow the cutting tool to approach the workpiece from multiple angles, enabling the machining of undercuts, curved surfaces and intricate details in a single setup. For example:

- 3-axis milling: Moves the cutting tool in three directions — X, Y and Z — suitable for many standard components.

- 4-axis milling: Adds an additional rotational axis — A-axis — useful for creating holes and features on multiple sides of a part.

- 5-axis milling: Adds additional rotation around two axes — A-axis and B-axis — ideal for extremely complex parts.

- 7-axis milling: Has all the capabilities of 5-axis machining, but with two additional axes — offers maximum flexibility and precision.

This ability to produce highly complex shapes makes CNC milling indispensable for industries that require precision components, such as turbine blades and optical housings.

5. Reduced Human Error

Even the most skilled machinist is prone to mistakes. Fatigue, distraction or a simple miscalculation can lead to costly errors in traditional milling.

CNC milling minimizes human involvement in the actual machining process. Once the design file and toolpaths are uploaded, the computer executes the operation exactly as programmed. The result is fewer errors, less wasted material and reduced rework.

6. Flexibility in Material Compatibility

Another advantage of CNC milling is its ability to machine a wide range of materials, including:

- Metals: Aluminum, titanium, copper, bronze, brass, stainless steel, tungsten and more.

- Plastics: Delrin®, Noryl, PEEK, PVC, UHMW, Teflon and many others.

This flexibility allows manufacturers to meet diverse industry needs while maintaining the same high level of precision and consistency. Traditional milling machines are often limited in the types of materials they can effectively handle.

7. Scalability for Prototyping and Production

Whether you need a single prototype or a high-volume production run, CNC milling can scale accordingly.

- Prototyping: CNC machining provides a fast and accurate way to create prototypes for testing and validation. Designers can quickly refine their ideas without long delays.

- Production: Once the prototype is approved, the same CNC program can be used to produce hundreds or thousands of identical parts with the same precision.

This scalability ensures that manufacturers can move from design to market quickly, reducing lead times and costs.

8. Improved Safety

Traditional milling requires machinists to remain close to the machine, exposing them to risks from flying debris, sharp tools and heavy equipment.

CNC milling improves safety by minimizing operator involvement during cutting operations. Machinists can oversee the process from a safe distance, and machines are often equipped with protective enclosures to contain debris.

This not only enhances workplace safety, but also reduces the likelihood of accidents that can halt production.

9. Seamless Integration with Digital Manufacturing

In today’s Industry 4.0 era, digital integration is becoming increasingly important. CNC milling is fully compatible with CAD/CAM software, making it easier to transition from digital design to physical production.

This integration streamlines the entire workflow — from concept to prototype to finished part — and ensures greater accuracy at every stage.

Traditional milling lacks this seamless connection, which often results in slower processes and increased opportunities for error.

Applications of CNC Milling Across Industries

CNC milling’s advantages have made it the preferred choice in numerous industries, including:

- Aerospace: Producing lightweight, high-strength parts with exact tolerances.

- Medical: Manufacturing surgical instruments, implants and precision devices.

- Defense: Creating reliable, mission-critical components for vehicles and weapons systems.

- Optical: Machining tiny, intricate parts used in instruments like microscopes, telescopes and cameras.

Each of these industries demands reliability, accuracy and consistency — qualities that CNC milling delivers better than traditional methods.

When Should You Choose CNC Milling Over Traditional Milling?

If your project requires:

- Tight tolerances

- Complex geometries

- High-volume production

- Rapid prototyping

- Multi-material compatibility

Then CNC milling is the clear choice.

While traditional milling still has a place in low-cost, low-complexity applications, it simply cannot compete with the versatility and capabilities of CNC milling for modern manufacturing needs.

Driving the Future of Manufacturing with CNC Milling

The transition from traditional milling to CNC milling represents a major shift in the manufacturing world. By offering unparalleled precision, repeatability, scalability and efficiency, CNC machining empowers manufacturers to meet the demands of today’s industries with confidence.

At P4Swiss / Lindel CNC Machining, we specialize in providing high-quality CNC milling services for complex and high-precision components. Our team leverages advanced multi-axis CNC machines to bring your designs to life — whether you need a single prototype or a full production run.

If you’re looking for a manufacturing partner who understands the demands of modern industries, P4Swiss / Lindel CNC Machining is the solution.

Contact us today to learn more about our multi-axis machining capabilities.

If you have any questions or would like to submit a CNC request for quote (RFQ), please do not hesitate to contact Tony Torrez at tony@p4swisslindel.com, call us at (520) 792-3160 or click the “Request a Custom CNC Quote Today” button below.