Choosing the right CNC machining material is one of the most critical decisions in manufacturing.

The material you select will determine your part’s durability and functionality.

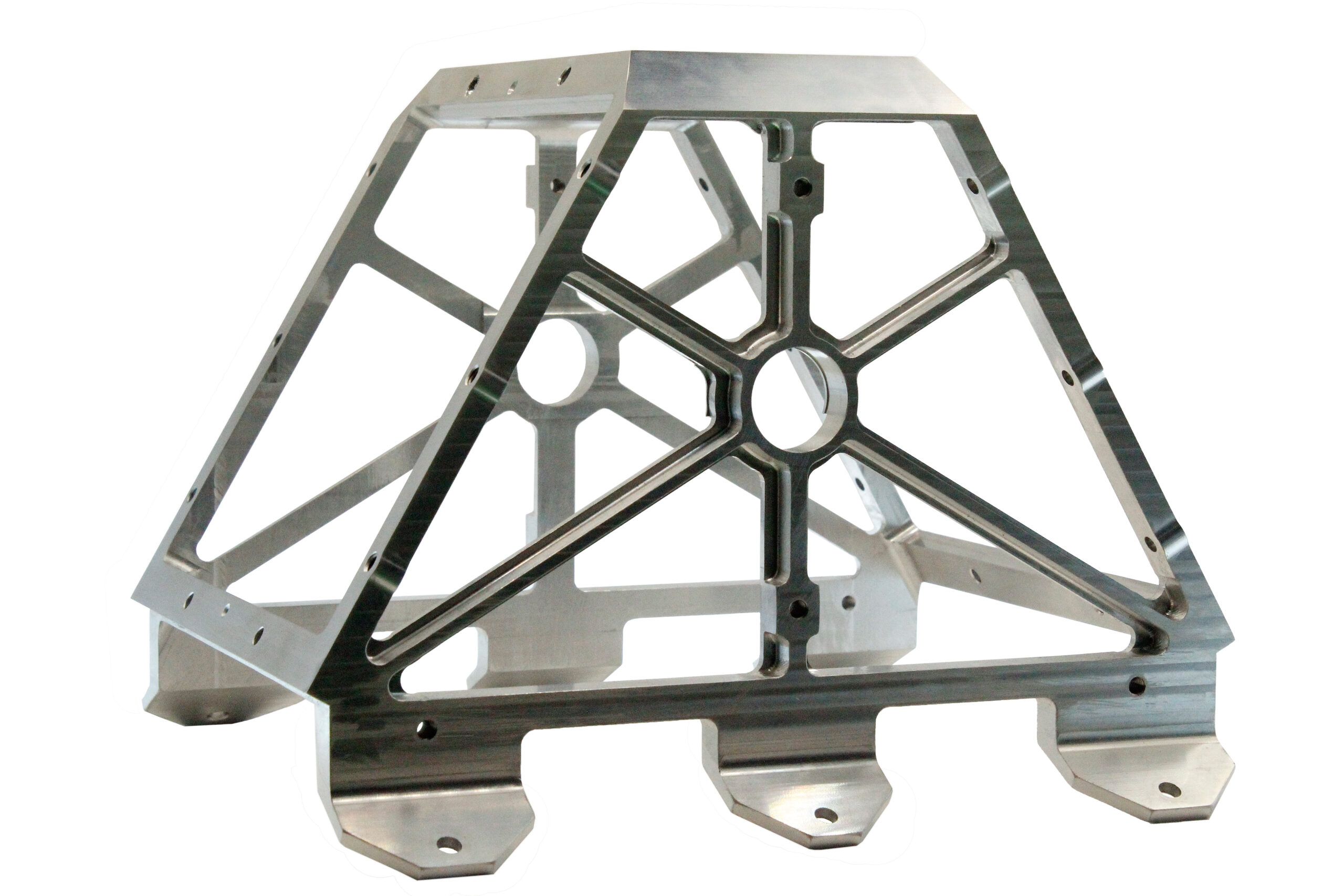

At P4Swiss | Lindel CNC Machining, we specialize in manufacturing a wide range of non-ferrous and exotic materials. Our expertise ensures that we can help you choose the best CNC machining material to meet your project’s specific needs.

Table of Contents

Understanding the Importance of CNC Machining Material Selection

Selecting the right CNC machining material is essential for achieving optimal performance in your final product. The material will impact factors such as strength, weight and corrosion resistance.

Whether you need a high-strength alloy for aerospace applications or a lightweight plastic for medical devices, choosing the right material ensures that your components meet required specifications and withstand their operating conditions.

A well-versed CNC machine shop, like P4Swiss | Lindel CNC Machining, can provide expert insights and recommendations on material selection. Our expertise in material properties and machining techniques allows us to improve the durability and performance of your finished parts.

Factors to Consider When Choosing a CNC Machining Material

When selecting a CNC machining material, several key factors should guide your decision:

1. Strength and Durability

The strength and durability of a material determine how well it can withstand stress and wear over time. If your component will experience high loads or harsh environments, selecting a robust material like stainless steel or titanium is ideal. On the other hand, if you need lightweight strength, aluminum provides an excellent balance between durability and weight reduction.

2. Corrosion Resistance

Certain industries, such as aerospace and medical, require materials that resist corrosion to ensure longevity and reliability.

Stainless steel, titanium and red metals (copper, bronze and brass) offer excellent corrosion resistance, making them ideal choices for applications exposed to moisture or chemicals.

3. Weight

Reducing weight without compromising strength is crucial in many applications, particularly in aerospace and automotive manufacturing.

Aluminum and plastics - like Delrin®, PEEK and UHMW - are excellent choices when weight reduction is a priority. These materials offer durability, while keeping the overall component lightweight.

4. Thermal and Electrical Conductivity

For applications requiring heat or electrical conductivity, copper, brass and bronze are top choices. These metals are widely used in electrical components, heat exchangers and precision instruments.

Selecting a CNC machining material with high conductivity ensures efficiency in electronic and thermal applications.

5. Machinability and Manufacturing Efficiency

Some materials are easier to machine than others, which affect the production time.

Aluminum, brass and plastics are known for their excellent machinability, essentially reducing lead times. However, more challenging materials like titanium and stainless steel require advanced CNC machining techniques, which P4Swiss | Lindel CNC Machining can expertly handle.

Overview of CNC Machining Materials at P4Swiss | Lindel

At P4Swiss | Lindel CNC Machining, we specialize in working with a diverse range of materials to meet the unique needs of various industries.

Here’s a closer look at some of the top CNC machining materials we work with:

Aluminum

- Lightweight yet strong

- Durable

- Corrosion-resistant

- Excellent machinability

Titanium

- Extremely strong and durable

- Lightweight

- Highly corrosion-resistant

Stainless Steel

- High strength and durability

- Corrosion resistance

- Versatile and used across multiple industries

Copper

- High thermal and electrical conductivity

- Naturally corrosion-resistant

Bronze

- Excellent wear resistance

- Resistance to corrosion

- High strength and durability

Brass

- Great machinability

- Corrosion-resistant with an attractive finish

- Superior thermal and electrical conductivity

Plastics (Delrin®, Noryl®, PEEK, PVC, UHMW)

- Lightweight

- Resistant to chemicals and moisture

- Resistance to wear

Teflon®

- Low friction

- High chemical resistance

- Excellent insulator for electrical components

Matching CNC Machining Materials to Industry Applications

Different industries require specialized materials to make sure components meet performance expectations.

Below are common industry applications for the materials we machine at P4Swiss | Lindel CNC Machining.

Aerospace Industry

- Best materials: Aluminum, Titanium, Stainless Steel

- Why? These materials offer high strength-to-weight ratios and resistance to extreme temperatures.

Medical Industry

- Best materials: Stainless Steel, Titanium, Plastics (PEEK, Delrin®, UHMW)

- Why? Biocompatibility, sterilization resistance and durability are crucial for the medical industry, especially for medical implants and surgical tools.

Defense Industry

- Best materials: Titanium, Stainless Steel, high-strength Plastics

- Why? Extreme durability, corrosion resistance and precision are essential for defense applications.

Optical Industry

- Best materials: Aluminum, Brass, Stainless Steel, Plastics (Delrin®, PEEK, UHMW)

- Why? The optical industry requires materials that provide excellent dimensional stability, durability and resistance to environmental factors.

Partner with P4Swiss | Lindel for Expert Material Selection

Choosing the right CNC machining material is vital to ensuring the success of your project.

At P4Swiss | Lindel CNC Machining, we specialize in manufacturing a diverse range of non-ferrous and exotic materials, providing expert recommendations to help you achieve the best results.

Our team understands the nuances of different materials and can advise you on the ideal choice for your application. Whether you need precision aerospace components, durable medical implants or high-performance defense parts, we have the experience and expertise to deliver high-quality results.

If you're ready to discuss your project and material requirements, contact P4Swiss | Lindel CNC Machining today. Let us help you select the best CNC machining material for your next manufacturing endeavor.

If you would like to submit a custom CNC request for quote (RFQ), please do not hesitate to contact Tony Torrez at tony@p4swisslindel.com, call us at (520) 792-3160 or click the “Request a Custom CNC Quote Today” button below.