Table of Contents

In today's competitive manufacturing landscape, choosing the right production method can significantly impact the success, cost and efficiency of your project. While large-scale production runs offer high output at a lower cost per unit, custom CNC machining provides the flexibility, precision and quality that many specialized applications require.

This guide explores the key differences between custom CNC machining and mass production. Whether you're developing a prototype, planning a limited run or scaling for the long term, understanding these two approaches will help you make an informed decision that aligns with your product goals, tolerances and budget.

What Is Custom CNC Machining?

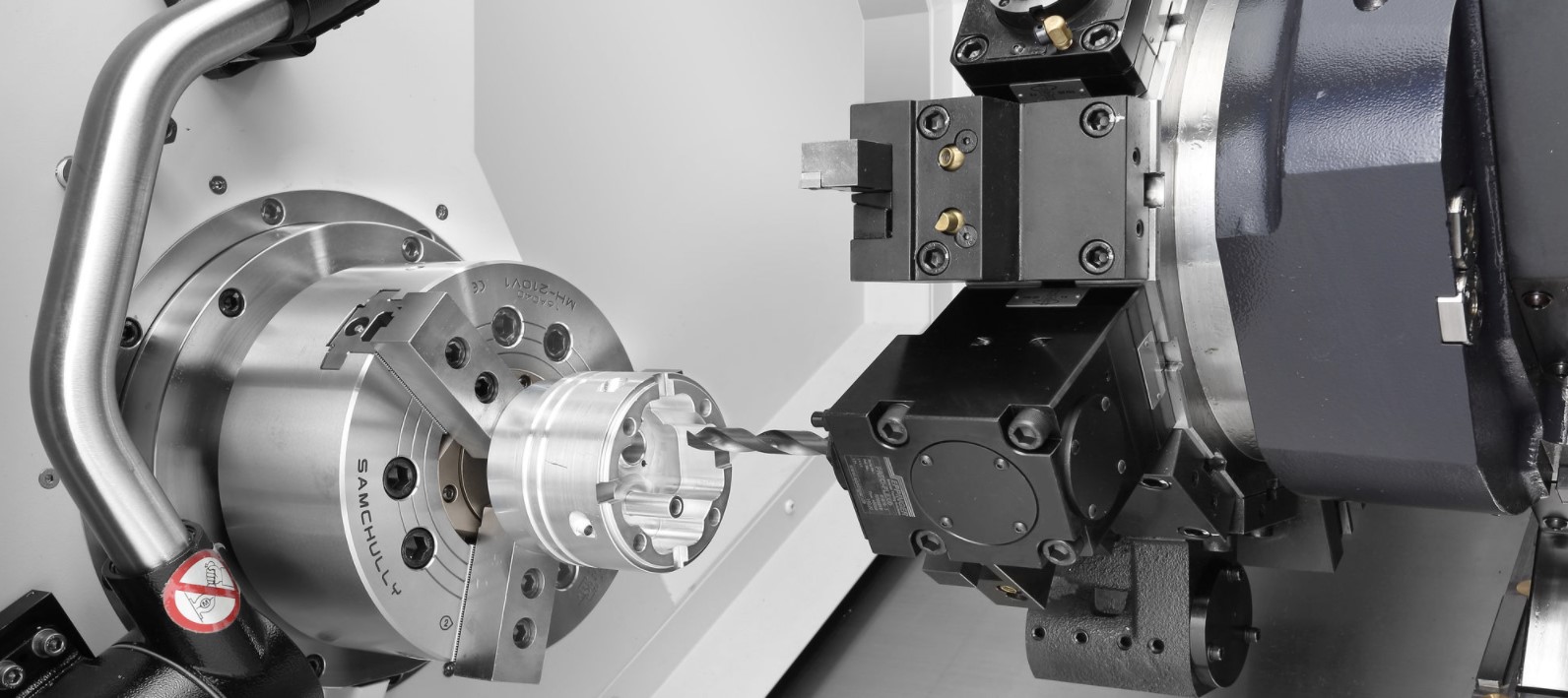

Custom CNC machining involves using computer numerical control (CNC) technology to create parts with high precision.

Engineers input detailed CAD (Computer-Aided Design) files into CNC machines, which then cut, drill and mill materials to exact specifications.

This approach is often used for prototyping or low-to-medium production volumes, making it ideal for industries that demand exact tolerances and highly specialized components, including medical, aerospace, defense and optics. At P4Swiss/Lindel CNC Machining, our facility specializes in non-ferrous and exotic materials such as aluminum, copper, titanium, plastics, stainless steel and more.

What Is Mass Production?

Mass production is the process of manufacturing large quantities of products quickly and cost-effectively, making this approach ideal for high-volume production runs.

Once setup is complete, the same part can be produced repeatedly, delivering consistent results at scale.

Key Differences Between Custom CNC Machining and Mass Production

| Category | Custom CNC Machining | Mass Production |

|---|---|---|

| Volume | Low to Medium | High |

| Flexibility | High — easily modifiable | Limited once setup is finalized |

| Precision & Customization | Extremely high | High precision, but limited customization |

| Lead Time | Longer — due to setup, testing & prototyping | Shorter once production begins |

| Cost per Unit | Higher cost per unit | Lower cost per unit over large volumes |

| Material Options | Broad — suited for exotic materials | Broad — focuses on scalable materials |

| Best Use Case | Complex, high-precision parts | Standardized parts |

When to Choose Custom CNC Machining

1. Rapid Prototyping

When you need to test a concept or tweak a design, custom CNC manufacturing offers a fast and accurate way to bring your idea to life.

2. Short Runs and Limited Batches

If your product doesn’t require thousands of parts, CNC machining allows you to produce just what you need.

3. High-Precision Components

Industries such as medical device manufacturing, aerospace and defense demand tolerances as tight as +/- .0001”. CNC machining ensures this level of accuracy.

4. Specialized Materials

If your component needs to be made from titanium, Delrin®, PEEK or other exotic materials, custom CNC manufacturing is often the best (or only) option.

When to Choose Mass Production

1. High Demand Products

When your product is aimed at a mass market and needs to be produced at scale, mass production methods are more cost effective.

2. Simple Part Geometry

Parts that don’t require extremely tight tolerances or have simple shapes can be mass-produced quickly and efficiently.

Industry Applications: Custom CNC Machining vs. Mass Production

Medical Industry

- Custom CNC Machining: Ideal for surgical instruments, implants and device housings that require strict tolerances and biocompatible materials.

- Mass Production: Useful for disposable items such as syringes, tubing and cases where tight tolerances are not critical.

Aerospace Industry

- Custom CNC Machining: Essential for components like brackets, housings and fasteners that demand precision and lightweight materials.

- Mass Production: Suitable for interior parts or components that are less critical to performance and safety.

Optical Industry

- Custom CNC Machining: Needed for precision mounts, lens holders and fine-threaded components where alignment is crucial.

- Mass Production: Used for lens covers and casings that do not impact optical performance.

Defense Industry

- Custom CNC Machining: Critical for weapon parts, guidance system housings and specialized mounts requiring military-grade durability.

- Mass Production: Good for large-scale equipment casings or basic structural parts.

Making the Right Choice for Your Project

To decide between custom CNC manufacturing and mass production, consider the following:

01) How many parts do you need?

- Fewer than 1,000? Custom CNC manufacturing is likely your best choice.

- More than 10,000? Mass production may be more cost-effective.

02) What tolerances and specifications are required?

- Tight tolerances and complex geometries = custom CNC manufacturing.

- Basic shapes and loose tolerances = mass production.

03) What materials does your part require?

- Exotic or specialized materials = custom CNC manufacturing.

- Standard plastics or metals = mass production.

Material Comparison

CNC manufacturing allows for a wide range of material options:

- Aluminum: Lightweight and strong — ideal for aerospace and optical components.

- Titanium: High strength-to-weight ratio and corrosion resistance for defense and medical uses.

- Stainless Steel: Durable and corrosion-resistant — commonly used across industries.

- Plastics (Delrin®, PEEK, UHMW): Excellent for non-conductive or chemically resistant parts.

Why Choose P4Swiss/Lindel CNC Machining?

At P4Swiss/Lindel CNC Machining, we specialize in CNC manufacturing for complex, high-precision parts. Our team has decades of experience machining non-ferrous and exotic materials for industries like medical, aerospace, optical and defense.

We combine state-of-the-art multi-axis CNC machines with expert machinists to deliver quality parts that meet exacting standards. Whether you need a single prototype or a large-scale production run, we’re here to support your manufacturing needs with responsiveness, reliability and precision.

Next Steps with P4Swiss/Lindel CNC Machining

Both custom CNC machining and mass production have their place in modern manufacturing. By understanding the strengths and limitations of each, you can choose the right process to meet your requirements.

When you’re ready to start, P4Swiss/Lindel CNC Machining is ready to help.

Ready to Start Your CNC Machining Project?

Let’s make your next project a success.

If you have any questions or would like to submit a CNC request for quote (RFQ), please do not hesitate to contact Tony Torrez at tony@p4swisslindel.com, call us at (520) 792-3160 or click the “Request a Custom CNC Quote Today” button below.