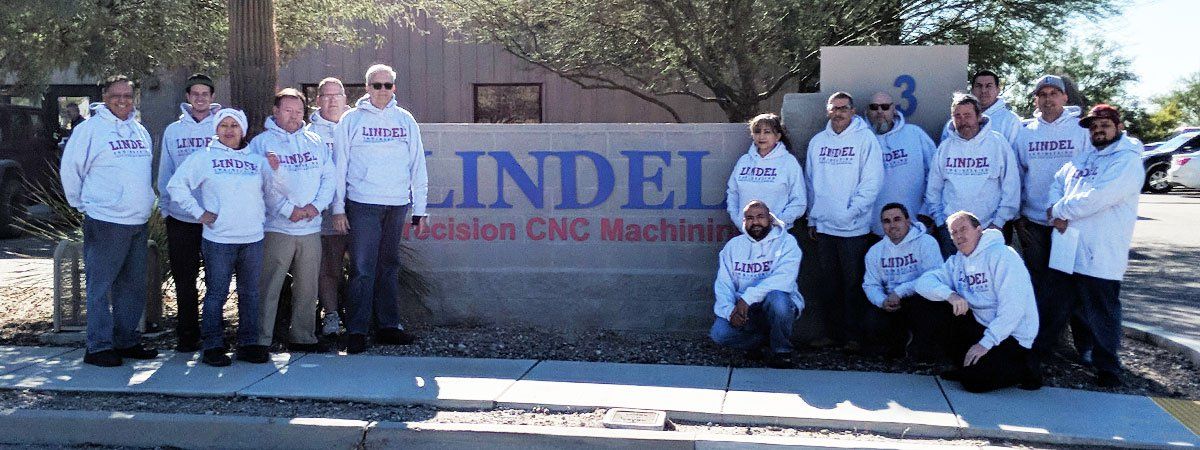

About P4Swiss / Lindel CNC Machining

P4Swiss / Lindel CNC Machining brings over three decades of expertise to the precision manufacturing industry. Originally founded as Lindel Precision CNC Machining in 1987, the company merged with Precision 4 Swiss in 2019 to form a powerhouse in CNC machining solutions. Together, we are committed to delivering high quality CNC machined parts at competitive prices, supporting industries that range from medical and aerospace to defense and optical.

Our parts are found in some of the most critical and cutting-edge applications, such as medical devices, laser housings, technical defense equipment and even intricate camera housings used in satellites. With that being said, this diverse portfolio clearly showcases our ability to meet the unique demands of various industries, while consistently maintaining the highest standards of precision and reliability.

Custom CNC Machining Solutions and Expert Support

At P4Swiss / Lindel CNC Machining, we understand that every project is unique. As a result, we specialize in custom-designed orders and provide end-to-end support for each and every client. From the initial stages of research and development to full-scale production runs, our team works closely with customers to make sure their specific requirements are met.

Our technical expertise, combined with decades of experience, enables us to offer innovative solutions to even the most complex challenges. Therefore, whether you need prototype development or high-volume production, we are fully equipped to handle every aspect of your CNC machining needs.

Diverse Materials for Superior Results

Our facility is equipped to machine parts in a wide variety of materials, including non-ferrous and exotic options. Consequently, this versatility allows us to create components with the specific properties your project demands. For example, some of the materials we specialize in include:

- Aluminum

- Copper

- Bronze

- Brass

- Titanium

- Teflon

- Red Metals

- Plastics

- Stainless Steel

This broad range of material capabilities will make sure that we can meet the needs of various industries, from lightweight and durable aerospace components to highly specialized medical devices.

Why Choose P4Swiss / Lindel CNC Machining?

Partnering with P4Swiss / Lindel CNC Machining comes with a host of benefits, such as:

- Uncompromising Quality: We have built a reputation for delivering precision parts that meet the highest standards.

- Outstanding Customer Service: Our team is dedicated to ensuring a seamless experience from project inception to completion.

- 100% American-Made: All our parts are proudly manufactured in the USA.

- Convenient Online Quotes: Our user-friendly online quote system will allow you to plan your project with ease.

- Flexible Payment Options: We accept most major credit cards to make transactions as smooth as possible.

- Timely Delivery: Our on-time delivery record will make sure your projects stay on schedule.

- Capability to Handle Challenges: No project is too complex for our team of experienced professionals.

Let’s Build Something Together

With over 30 years of experience, P4Swiss / Lindel CNC Machining is your trusted partner for precision CNC machining solutions. Whether you need prototypes, specialized materials or large-scale production, we have the expertise and capabilities to consistently deliver exceptional results.

Get started today — call, email or submit an online quote. Let us show you why P4Swiss / Lindel CNC Machining is the choice for quality, precision and reliability.

Our Mission: Providing Solutions By Machining The Extraordinary