As product designs become more advanced and performance requirements continue to tighten, manufacturers face increasing pressure to produce complex, high-precision components efficiently. Traditional machining methods often struggle to keep up with these demands. This is where multi-axis machining becomes a critical advantage.

Multi-axis machining allows manufacturers to produce intricate parts with greater accuracy, tighter tolerances and fewer setups. At P4Swiss / Lindel CNC Machining, we leverage 3-axis, 4-axis, 5-axis and 7-axis machining capabilities to meet the needs of industries that demand nothing less than precision and reliability.

In this guide, we’ll break down what multi-axis manufacturing is, how it works and why it plays such a vital role in modern manufacturing.

Table of Contents

What Is Multi-Axis Machining?

Multi-axis machining refers to CNC machining processes that move cutting tools or workpieces along more than the traditional three linear axes (X, Y and Z). While 3-axis machining remains effective for simpler components, multi-axis CNC machines introduce additional rotational axes that allow for more complex movement.

By adding these axes, machinists can access multiple sides of a part in a single setup. As a result, manufacturers achieve greater precision, improved surface finishes and significantly reduced production time.

At P4Swiss / Lindel CNC Machining, multi-axis manufacturing allows us to tackle complex geometries that would otherwise require multiple setups or secondary operations.

Why Multi-Axis Machining Matters in Precision Manufacturing

Modern components — especially those used in aerospace, medical, defense and optical applications — often feature complex contours, deep cavities and ultra-tight tolerances. Multi-axis manufacturing plays a crucial role in meeting these challenges.

Here’s why it matters:

- Reduces setup changes and part handling

- Improves dimensional accuracy and consistency

- Enables complex geometries and intricate features

- Enhances surface finishes

- Increases production efficiency

These advantages make multi-axis machining essential for both prototyping and high-volume production runs.

Multi-Axis Machining Methods

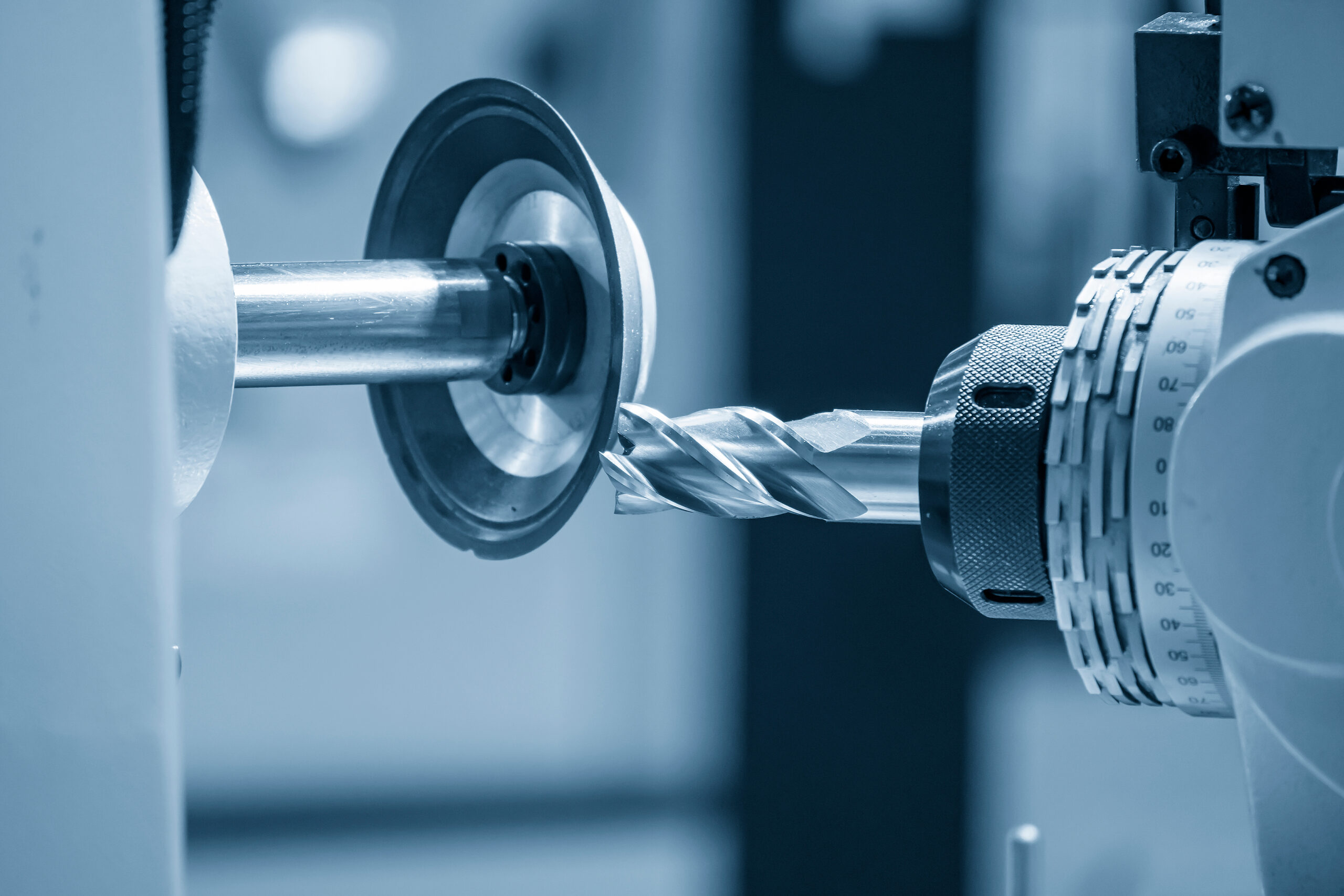

3-Axis Machining: The Foundation of CNC Manufacturing

3-axis machining moves the cutting tool along the X, Y and Z axes. This method works well for flat surfaces, simple pockets and straightforward part designs.

Key Benefits of 3-Axis Machining

- Cost-effective for simple components

- Efficient for basic milling operations

- Ideal for plates, brackets and housings

While 3-axis machining remains valuable, it can require multiple setups for complex parts. That’s where higher-axis machining delivers additional value.

4-Axis Machining: Improved Access and Efficiency

4-axis machining adds a rotational axis — typically rotating the workpiece around the X-axis. This allows machinists to work on multiple sides of a component without repositioning it manually.

Advantages of 4-Axis Machining

- Reduces setup time

- Improves alignment accuracy

- Ideal for cylindrical and symmetrical parts

At P4Swiss / Lindel CNC Machining, 4-axis machining allows us to produce components with more detail while maintaining consistency across production runs.

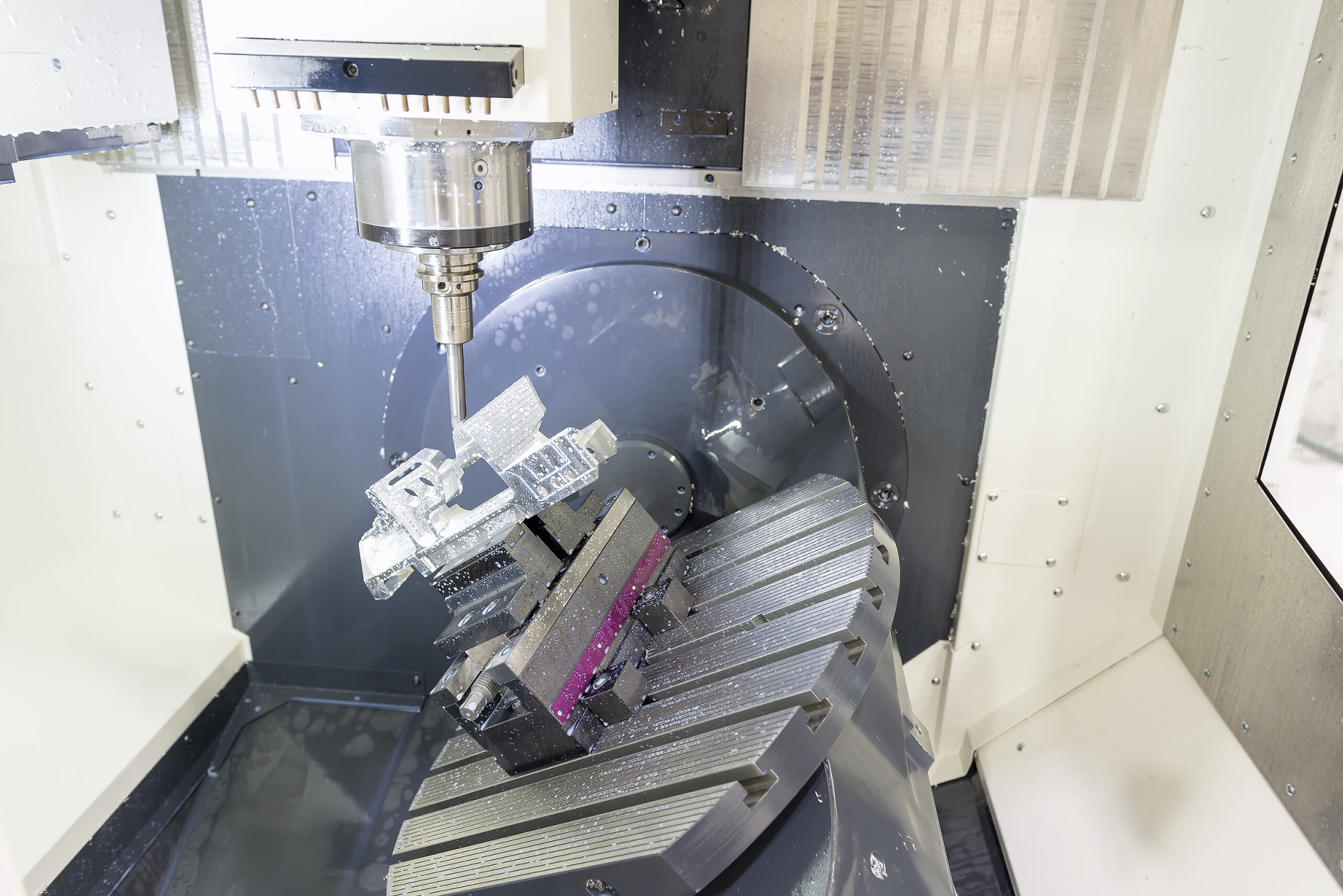

5-Axis Machining: Precision for Complex Geometries

5-axis machining represents a major leap forward in CNC technology.

By adding two rotational axes, machinists can approach the workpiece from nearly any angle.

This capability is especially valuable for parts with complex contours, deep cavities and tight tolerances.

Benefits of 5-Axis Machining

- Machines complex shapes in a single setup

- Improves surface finishes

- Achieves tighter tolerances

- Shortens lead times

Industries such as aerospace, medical and defense rely heavily on 5-axis machining to meet strict performance and safety requirements.

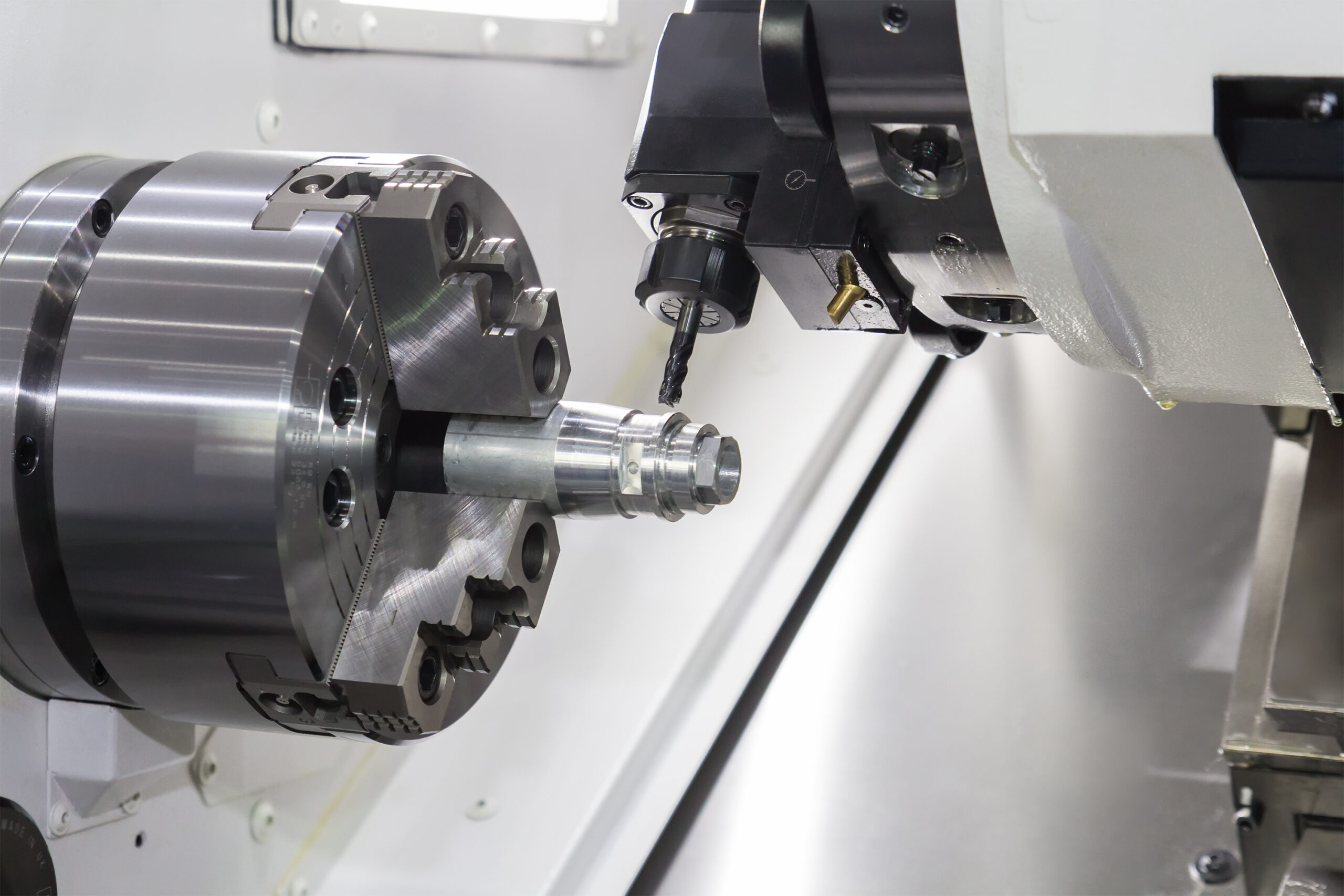

7-Axis Machining: Maximum Flexibility and Precision

7-axis machining combines multi-axis milling with advanced turning capabilities, allowing simultaneous movement across multiple axes. This approach is ideal for long, slender or highly complex parts.

Why 7-Axis Machining Stands Out

- Enables complete part machining in one cycle

- Minimizes secondary operations

- Improves concentricity and alignment

At P4Swiss / Lindel CNC Machining, 7-axis machining supports efficient production while maintaining the precision required for demanding applications.

Multi-Axis Machining vs. Traditional Machining

When comparing multi-axis manufacturing to traditional machining methods, the differences are significant.

| Feature | Traditional Machining | Multi-Axis Machining |

|---|---|---|

| Setup Changes | Multiple | Minimal |

| Part Accuracy | Moderate | Extremely High |

| Complex Geometry | Limited | Excellent |

| Production Speed | Slower | Faster |

| Surface Finish | Variable | Superior |

Multi-axis machining allows manufacturers to deliver higher-quality parts while reducing costs associated with labor and rework.

Industry Applications of Multi-Axis Machining

Multi-axis manufacturing supports a wide range of industries that require precision and consistency.

Aerospace components demand tight tolerances, lightweight materials and complex geometries. Multi-axis manufacturing enables efficient production of brackets, housings, structural components and flight-critical parts.

Medical parts often feature intricate designs and require biocompatible materials. Multi-axis manufacturing ensures accuracy, repeatability and smooth surface finishes for surgical tools, implants and device components.

Defense applications rely on durable, high-performance parts. Multi-axis machining allows for precision manufacturing of components used in communication systems, guidance equipment and tactical hardware.

Optical components require exact alignment and smooth finishes. Multi-axis manufacturing ensures precision in housings, mounts and adjustment components critical to optical performance.

Material Compatibility in Multi-Axis Manufacturing

Multi-axis manufacturing supports a wide variety of materials, including:

- Aluminum

- Stainless steel

- Titanium

- Copper and brass

- Engineering plastics

At P4Swiss / Lindel CNC Machining, our expertise across multiple materials allows us to recommend the best machining approach for performance, durability and cost efficiency.

From Prototyping to High-Volume Production

One of the greatest strengths of multi-axis manufacturing lies in its scalability. Whether you need a single prototype or a high-volume production run, multi-axis CNC machines provide consistency at every stage.

- Rapid prototyping validates designs faster

- Reduced setups improve production efficiency

- Automated processes maintain part uniformity

This flexibility allows manufacturers to transition seamlessly from development to full-scale production.

How P4Swiss / Lindel CNC Machining Delivers Precision

At P4Swiss / Lindel CNC Machining, multi-axis machining is a core part of our manufacturing strategy. Our advanced equipment, experienced machinists and rigorous quality controls ensure every part meets exact specifications.

We combine:

- 3-axis, 4-axis, 5-axis and 7-axis machining

- Advanced CAM programming

- Tight process controls

- Industry-specific expertise

This approach allows us to deliver complex parts with accuracy, efficiency and reliability.

Why Multi-Axis Machining Is the Future of Manufacturing

As industries continue to push the limits of design and performance, multi-axis machining will remain a key driver of innovation. Its ability to produce intricate components with unmatched precision makes it essential for modern manufacturing.

For companies seeking higher quality, faster turnaround and greater design freedom, multi-axis manufacturing provides a clear competitive advantage.

Partner with P4Swiss / Lindel CNC Machining

If your project requires complex geometry, tight tolerances and consistent quality, P4Swiss / Lindel CNC Machining has the multi-axis capabilities to deliver. From prototypes to production, our team is ready to support your most demanding machining challenges.

Contact us today to learn how multi-axis machining can elevate your next project.

If you have any questions or would like to submit a CNC request for quote (RFQ), please do not hesitate to contact Tony Torrez at tony@p4swisslindel.com, call us at (520) 792-3160 or click the “Request a Custom CNC Quote Today” button below.